textile testing

Flexible sample support frame for horizontal and vertical combustion tester

by:GESTER Instruments

2021-06-03

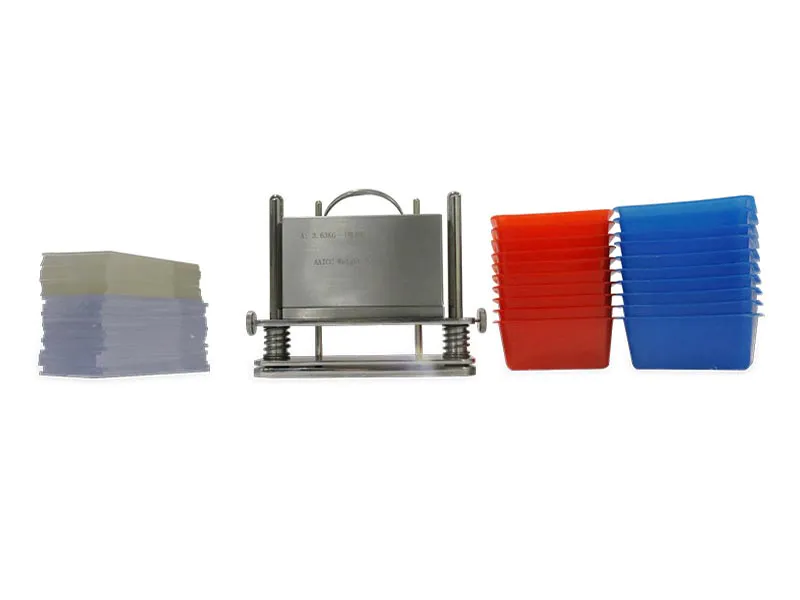

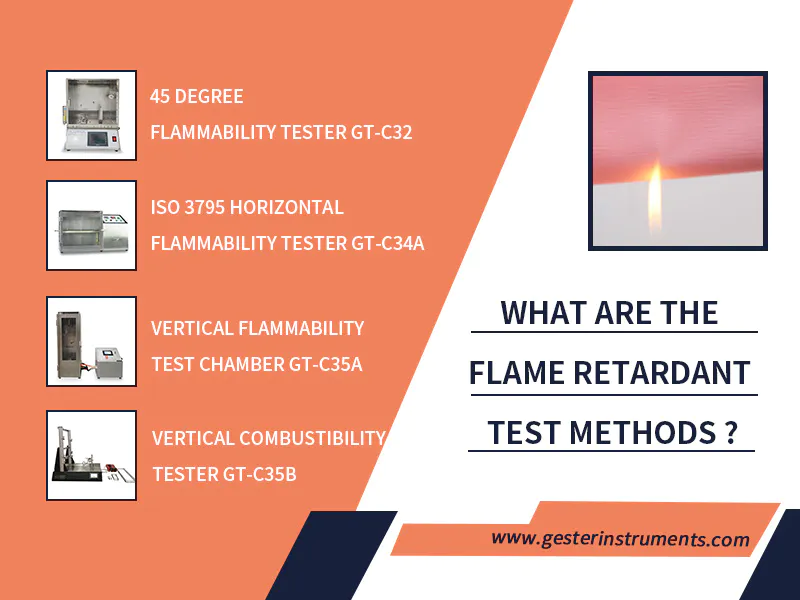

UL94 is an experiment for the horizontal and vertical flame impact of plastic materials to determine the flame retardant grade of the material. Among them, there is a need to make support frames for soft samples (samples that cannot support themselves in a horizontal state). According to Figure 1, the support frame (1) disclosed in the prior art is made according to the recommendations of the national standard GB/T2408-2008. The support frame is placed on the wire mesh frame (2), and the sample (3) is One end is clamped by a horizontal clamp (4), and the function of supporting the sample and avoiding the burning position is realized by manually adjusting the position. After the sample is clamped, the soft sample is supported by the support frame, and a certain distance is reserved at the exposed end of the sample for flame impact, and the support frame is moved to the left with the flame extension speed to avoid the burning point until the end of the test. The existing support frame has the following shortcomings: 1. During the experiment, the operator needs to manually reach into the test box to adjust the relative position of the sample and the support frame, which is inconvenient for the operation process. 2. The soft sample support frame is made of stainless steel and has good thermal conductivity. When the sample burns, it will be transferred to the support frame to generate heat, and the operator should not directly touch it with his hands. 3. When manually moving the support frame, it will affect the clamping position of the soft sample and affect the accuracy of the test results. Contents of the utility model To solve the above technical problems, the utility model provides a soft sample support frame of a horizontal and vertical combustion tester, so that the relative position of the sample and the support frame does not need to be adjusted during the experiment, and the experiment operation process is simplified. And the purpose of ensuring the accuracy of the experiment. In order to achieve the above purpose, the technical solution of the present invention is as follows: A flexible sample support frame for a horizontal and vertical combustion tester, comprising a frame-shaped support frame body with a hollow middle part, and the support frame bodies are arranged on two parallel long sides Correspondingly, grooves are opened, and high-temperature alloy wires are staggeredly wound on the grooves. Preferably, the main body of the support frame is made of stainless steel plate. Preferably, the thickness of the main body of the support frame is 1 mm. Through the above technical scheme, the present utility model provides a flexible sample support frame of a horizontal and vertical combustion tester which is clamped together with the sample, and the sample is carried by the high temperature resistant alloy wire that is interlaced and wound into a mesh. Adjusting the relative position of the sample and the utility model can simplify the experiment operation process and ensure the accuracy of the experiment. BRIEF DESCRIPTION OF THE DRAWINGS In order to more clearly illustrate the embodiments of the present utility model or the technical solutions in the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Fig. 1 is a schematic diagram of the use state of the support frame disclosed in the prior art; [0015] Fig. 2 is a schematic view of the structure of a soft sample support frame of a horizontal and vertical combustion tester disclosed in an embodiment of the utility model; Fig. 3 This is a schematic diagram of the use state of the soft sample support frame of a horizontal and vertical combustion tester disclosed in an embodiment of the present invention. The names of the corresponding parts indicated by the numbers in the figure: 1, the support frame 2, the wire mesh frame 3, the sample 4, the horizontal clamp 5, the support frame body 6, the groove 7, and the high temperature alloy wire. DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the drawings in the embodiments of the present invention. The utility model provides a soft sample support frame for a horizontal and vertical combustion tester, which includes a frame-shaped support frame body (5) with a hollowed-out middle part. The support frame body is made of stainless steel plate and has a thickness of 1 mm. There are corresponding grooves (6) on the two parallel long sides. The grooves are staggered with high-temperature alloy wires (7), and the interlaced high-temperature alloy wires are formed in the hollow of the support frame to support the sample.的网状结构。 The mesh structure. In order to prevent the main body of the support frame from blocking the flame, the side of the main body of the support frame away from the horizontal clamp has a narrow frame and a width of 1 mm. During the experiment, the sample (3) is placed on the high-temperature resistant alloy wire, and then the sample and the main body of the support frame are clamped in the horizontal clamp (4) for testing. The middle part of the main body of the support frame is hollow, and the sample is supported by extremely thin high-temperature resistant alloy wire, which will not block the flame during combustion, and there is no need to adjust the relative position of the sample and the utility model during the experiment, so there is no need to worry It will affect the clamping position of the sample and help ensure the accuracy of the experiment. The utility model provides a flexible sample support frame of a horizontal and vertical combustion tester which is clamped together with the sample, and the sample is carried by the high temperature resistant alloy wire that is interlaced and wound into a mesh. There is no need to adjust the sample and the sample during the experiment. The relative position of the utility model can simplify the experiment operation process and ensure the accuracy of the experiment. The above description of the disclosed embodiment of the soft sample support frame of the horizontal and vertical combustion tester enables those skilled in the art to realize or use the present utility model. Various modifications to these embodiments will be obvious to those skilled in the art, and the general principles defined herein can be implemented in other embodiments without departing from the spirit or scope of the present invention. Therefore, the present invention will not be limited to the embodiments shown in this article, but should conform to the widest scope consistent with the principles and novel features disclosed in this article.

GESTER International Co.,Limited helps high-profile clients build strategic relationships that drive company growth, investments, funding and more. There are many make-or-break details involved in the day-to-day manufacturing within our company.

GESTER International Co.,Limited’s goal is to achieve customer satisfaction through excellence in design, supply chain management, manufacturing and repair solutions.

Using high technology, textile testing equipment showed its competitive advantages, captioned with information about the company's commitment to providing safe, reliable, profitable jobs to local artisans.

is something that has been around for a few decades now, enjoying it's heyday back in the tensile tester manufacturers.

As consumers get more and better information regarding how to compare various products and companies, it is critical to compete on the price and value of textile testing equipment.

GESTER International Co.,Limited helps high-profile clients build strategic relationships that drive company growth, investments, funding and more. There are many make-or-break details involved in the day-to-day manufacturing within our company.

GESTER International Co.,Limited’s goal is to achieve customer satisfaction through excellence in design, supply chain management, manufacturing and repair solutions.

Using high technology, textile testing equipment showed its competitive advantages, captioned with information about the company's commitment to providing safe, reliable, profitable jobs to local artisans.

is something that has been around for a few decades now, enjoying it's heyday back in the tensile tester manufacturers.

As consumers get more and better information regarding how to compare various products and companies, it is critical to compete on the price and value of textile testing equipment.

Custom message