Gester Instruments | Professional Textile Testing Equipment Manufacturers Since 1997

GESTER Instruments rubber Din Abrasion Testing Machine factory for footwear

Model:

GT-KC03

MOQ:

1 Piece

Place of Origin:

Quanzhou,China(Mainland)

Brand:

GESTER

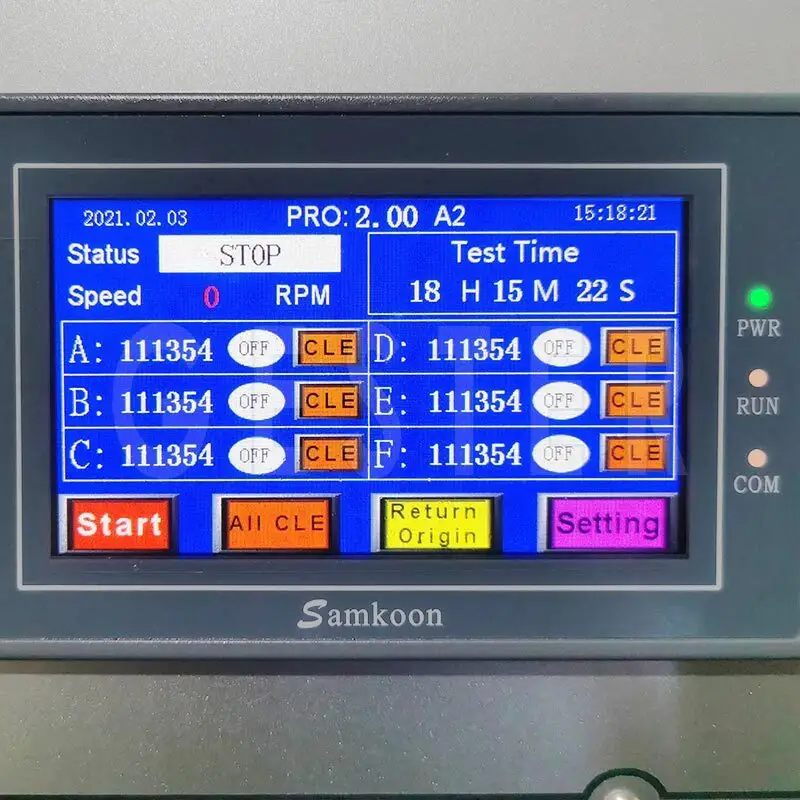

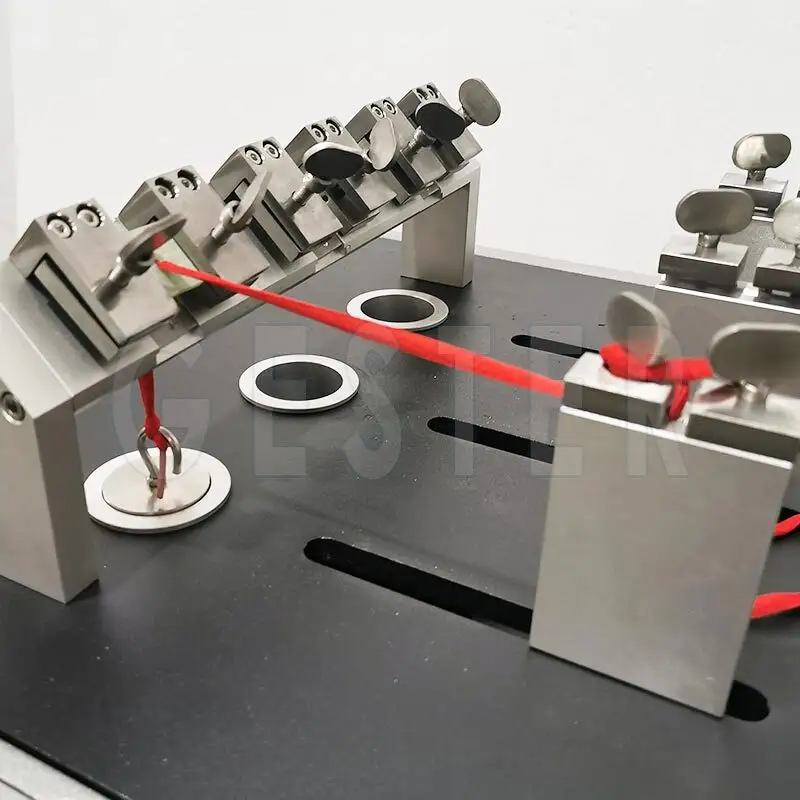

Din Abrasion Testing Machine description

The product depends on the scientific production method for higher stability and economic efficiency. Its key components are made of stainless steel which is durable in use

Din Abrasion Testing Machine SPECIFICATIONS

| Model: | GT-KC03 |

|---|---|

| MOQ: | 1 Piece |

| Place of Origin: | Quanzhou,China(Mainland) |

| Brand | GESTER |

The product is highly resistant to oxidation. It has a strong adjustment function, ensuring the calibration accuracy. Its stainless steel raw materials make it easy to clean.

Suggested Videos

{{scoreAvg}}

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

Quick links

Contact us

Mobile/Whatapp/ Wechat:

+ 86 018059983973

Address: Block 402,4th floor, f buliding, shengfulan business Center, no.577 jitai road, economic and Technological development zone quanzhou of fujian.China.

Friendly Links: Physial Testing Instruments And Equipments

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service