Gester Instruments | Professional Textile, Footwear and PPE Testing Equipments Manufacturers Since 1997

Products

PPE Testing Equipment

Heat Contact Machine

Heat Radiation Tester

Sweating Guarded Hot Plate

Heat Transmission Resistance Tester

TPP Thermal Protection Tester

Against Molten Metal

Electrostatic Charge Attenuation Tester

Blood Penetration Resistance Tester

Dry State Lint Tester

Impact Penetration Tester

Dry Microbial Penetration Resistance Tester

Wet-resistant Bacterial Penetration Tester

Static Decay Tester

Fabric Friction Electronic Charge Density

Universal Test Machine

Tensile Test Machine

Martindale Tester

Humidity Test Chamber

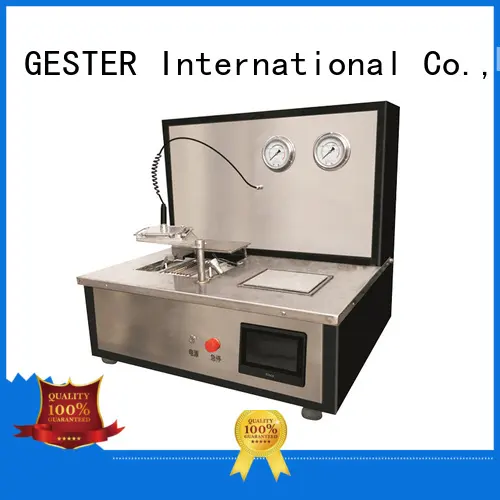

electronic protective clothing tester for test

Model:

GT-RC02

MOQ:

1 Piece

Place of Origin:

Quanzhou,China(Mainland)

Brand:

GESTER

{{scoreAvg}}

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

Quick links

Contact us

Mobile/Whatapp/ Wechat:

+ 86 018059983973

Address: Block 402,4th floor, f buliding, shengfulan business Center, no.577 jitai road, economic and Technological development zone quanzhou of fujian.China.

Friendly Links: Physial Testing Instruments And Equipments

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service