Gester Instruments | Professional Textile Testing Equipment Manufacturers Since 1997

custom martindale pilling test method standard for lab

Model:

GT-C26B

MOQ:

1 Piece

Place of Origin:

Quanzhou,China(Mainland)

Brand:

GESTER

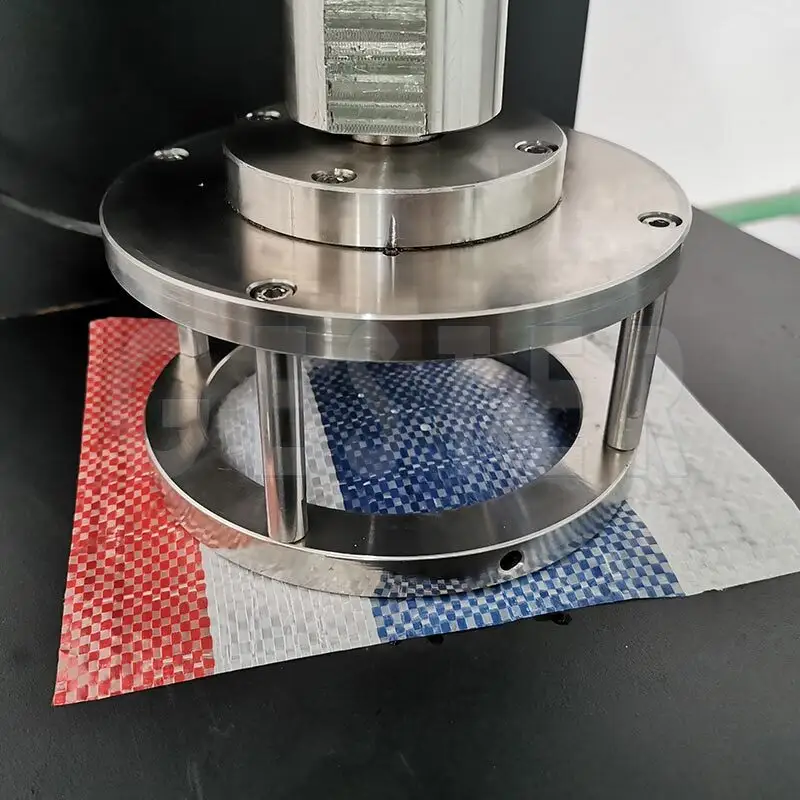

martindale pilling test method

description

The product is built to last for a long time. Its components do not easily wear over time and do not demand frequent maintenance, but can work for long. It receives popularity among customers from Europe, America, Middle East, and so on

martindale pilling test method

SPECIFICATIONS

| Model: | GT-C26B |

|---|---|

| MOQ: | 1 Piece |

| Place of Origin: | Quanzhou,China(Mainland) |

| Brand | GESTER |

It has an alarm report function when finishing the test work. Adopting high-quality imported stainless steel, it has a long service life. Adopting stainless steel as the key materials, it is not easy to crack.

Suggested Videos

{{scoreAvg}}

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

Quick links

Contact us

Mobile/Whatapp/ Wechat:

+ 86 018059983973

Address: Block 402,4th floor, f buliding, shengfulan business Center, no.577 jitai road, economic and Technological development zone quanzhou of fujian.China.

Friendly Links: Physial Testing Instruments And Equipments

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service