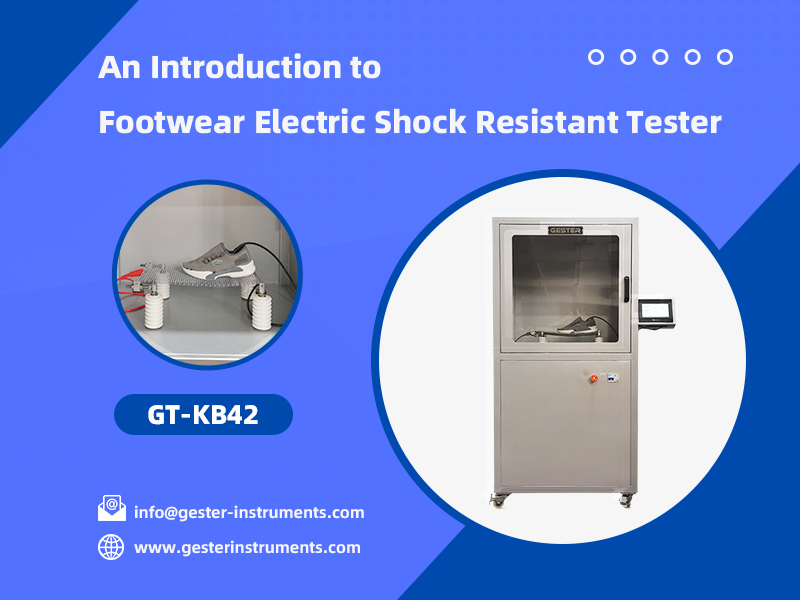

Footwear Electric Shock Resistant Tester Overview

Shoes electric shock withstand tester by applying a specific frequency and voltage on the sample, the tester gradually increases voltage to the specified level to determine whether the sole can withstand the specified voltage within a certain period of time, so as to judge the safety of shoes in a specific environment.

Shoe Dielectric Resistance Test Applications

Footwear Electric Shock Resistant Tester is mainly used for electric shock withstand test of the following footwear products:

Insulated safety shoes: suitable for electric power maintenance, building construction and other industries to ensure effective protection in high-voltage environments.

Protective boots: applicable to high-risk environments such as mining, petrochemical, etc., providing comprehensive protection against electric shock.

Other electrical insulating footwear: Ensure compliance with relevant industry standards to ensure user safety.

Standards

GT-KB42 Footwear Electric Shock Resistant Tester complies with many international and national standards:

ANSI Z41 Chapter 4 (American National Standard)

CSA Z195-14 Chapter 6.5 (Canadian Standard)

AS/NZS 2210.2 Chapter 5.11 (Australia/New Zealand Standard)

GB 12011, GB/T 20991 Chapter 5.11 (Chinese National Standard)

ASTM F2412 Chapter 9, ASTM F2413 Chapter 5.5 (American Society for Testing and Materials standards)

NOM-113-STPS-2009 Chapter 8.5 (Mexican Standard)

These standards cover the testing requirements for voltage resistance, leakage current and durability of footwear.

Product Advantages

Accurate Measurement

Adopts high precision voltage and current measurement system to ensure data reliability.

Intelligent control

Equipped with automatic voltage adjustment and real-time monitoring function to improve testing efficiency.

Multi-standard compatibility

Complies with many global testing standards, applicable to international market demand.

Safety Protection Design

Built-in leakage protection system to ensure the safety of operators.

How to Operate Footwear Electric Shock Resistant Tester

Warning: Please note that the specific steps need to be in accordance with the operating instructions, and confirm with the relevant personnel, not to be used arbitrarily!

Place insulating mat on the floor in front of the device. Turn on the main power switch and rotate the emergency stop button clockwise to release it.

Setting page test parameter page, screen saver parameter page, alarm page, calibration surface, set test parameters (test voltage size setting, test current size setting, test time setting)

Press the Run button to start the test, the voltage value starts to increase at the rate of 1000/S, and after reaching 75% of the set value, it increases the voltage value by 100V/S. When the voltage value reaches the set voltage value, it starts timing. The test completes automatically when the preset duration is reached. (provided that the specimen is not penetrated).

For the breakdown test: Set the voltage to the device's maximum or the expected breakdown voltage of the sample. In the test process, such as the specimen is penetrated (due to the instantaneous generation of short-circuit equipment fuse will burn out), please turn off the power. (Within a certain period of time) If the specimen will be penetrated, the breakdown voltage value of the specimen exceeds the maximum voltage value and current value of this equipment.

Open the power control cover, replace the fuse, and close the power control cover. Turn on the power supply, the maximum voltage value displayed on the screen is the voltage value of the specimen being penetrated, and the maximum current value is the maximum current value of the specimen being penetrated.

Take out the specimen, the main note: when the equipment is energized, take out the specimen need to wear insulating gloves. Check the damage of the specimen after the breakdown.

Copyright © 2025 GESTER International Co.,Limited | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.