Related Products

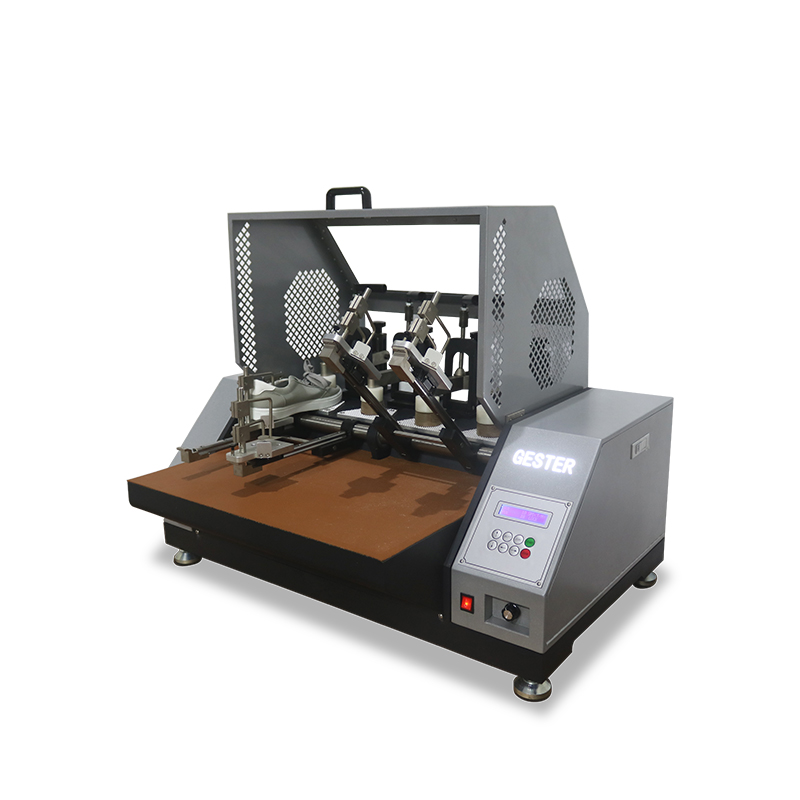

| Model: | GT-KA01-2 |

|---|---|

| MOQ: | 1 Piece |

| Place of Origin: | Quanzhou,China(Mainland) |

| Brand | Gester |

Copyright © 2025 GESTER International Co.,Limited | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.