Introduction

Using a Random Tumble Pilling Tester is essential for evaluating fabric performance accurately. This article will guide you through the process, ensuring you make the most of this testing equipment.

Understanding the Random Tumble Pilling Tester

Tumble tester to determine the pilling and fuzzing characteristics of textile fabrics. Precision high-speed impeller for agitating the test specimens against cork lining for a pre-determined time controlled by a timer and audible alarm. Compressed air is also injected into the chamber to assist in the tumbling action. Laboratory standard compressed air supply required.

Feature:

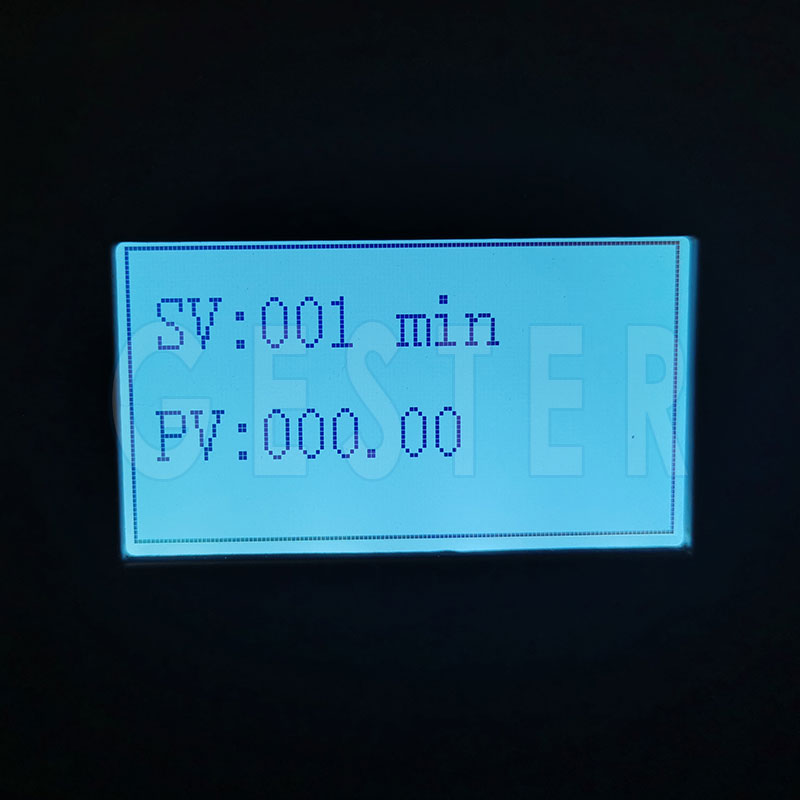

A. Intelligent interface to guide the user.

B.Flexible system maximizes throughput and minimizes downtime.

C.Interchangeable impellers for different global standards.

D. Stable propeller and rotation speed.

How to Use a Random Tumble Pilling Tester

I. Preparing the Test Specimens

Before conducting any tests, it is crucial to prepare the fabric samples properly. Cut representative swatches from the fabric and ensure they are free from any visible defects or irregularities. Each sample should be large enough to cover the testing area adequately.

II. Setting Up the Random Tumble Pilling Tester

A. Place the test specimens into the testing chamber of the ASTM D3512 Random Tumble Pilling Tester, ensuring they are securely attached to the testing plates or holders.

B. Set the desired test parameters, including the number of test cycles, test speed, and any specific test standards or protocols to be followed.

C. Double-check that the testing chamber is properly closed and secured.

III. Conducting the Test

A. Once the random pilling tester is set up, you can begin the evaluation process.

B. Start the testing machine, and allow it to run for the specified number of cycles.

C. Observe the testing process closely, ensuring that the specimens undergo the desired rubbing and tumbling action uniformly.

IV. Monitoring and Assessing Fabric Performance

A. After the test cycles are complete, carefully remove the fabric samples from the testing chamber.

B. Examine each specimen for the formation of pills, using both visual inspection and magnification if necessary.

C. Rate the pilling performance of each fabric sample according to the applicable standards or your own evaluation criteria.

D. Record and document the results accurately for future reference.

V. Analyzing the Results

A. Analyzing the data collected from the random pilling tester helps in understanding the fabric's performance and durability.

B. Compare the pilling performance of different fabric samples tested under the same conditions.

C. Identify any significant differences and make notes of the factors that may have influenced the results, such as fabric composition or finishing techniques.

D. Based on the test results, draw conclusions about the fabric's overall pilling resistance and performance.

E. Consider the intended application of the fabric and determine if it meets the required standards or specifications.

Using a Random Tumble Pilling Tester is a valuable tool in evaluating fabric performance. By following the outlined steps and carefully analyzing the results, you can make informed decisions about the quality and durability of fabrics, ensuring their suitability for various applications.