ISO 17694 / ISO 5402-1: Footwear Flexing Resistance Test Methods

During the wearing process of shoes, the soles (especially the forefoot area) and uppers (especially the toe bends) will undergo thousands of times of flexing and recovery as we walk, run, squat, etc. If the material has poor flex resistance, these areas may prematurely develop problems such as cracking, breaking, chalking, delamination, or chipping.

Two international standards, ISO 17694 and ISO 5402-1: provide the technical basis for testing the flexing resistance of footwear uppers, linings and leather materials.

ISO 5402-1

ISO 5402-1: Leather — Determination of flexing resistance — Part 1: Flexometer method

This standard specifies a method for testing the flexing resistance of leather, which is suitable for assessing the performance of leather during repeated flexing. The standard describes in detail the experimental equipment, the operating procedures and the determination of the results. The standard provides a harmonised technical basis for quality control and performance assessment of leather products.

ISO 17694

ISO 17694: Footwear-Test methods for uppers and lining-flexing resistance

This standard specifies in detail the methods used to test the flexing resistance of uppers and linings in footwear. By simulating the bending stresses to which footwear is subjected during everyday wear, it helps manufacturers to assess the durability of materials under prolonged use. The test method covers bending test conditions for a wide range of different types of footwear and provides detailed instructions on experimental procedures, equipment requirements and analysis of results.

1. Applications

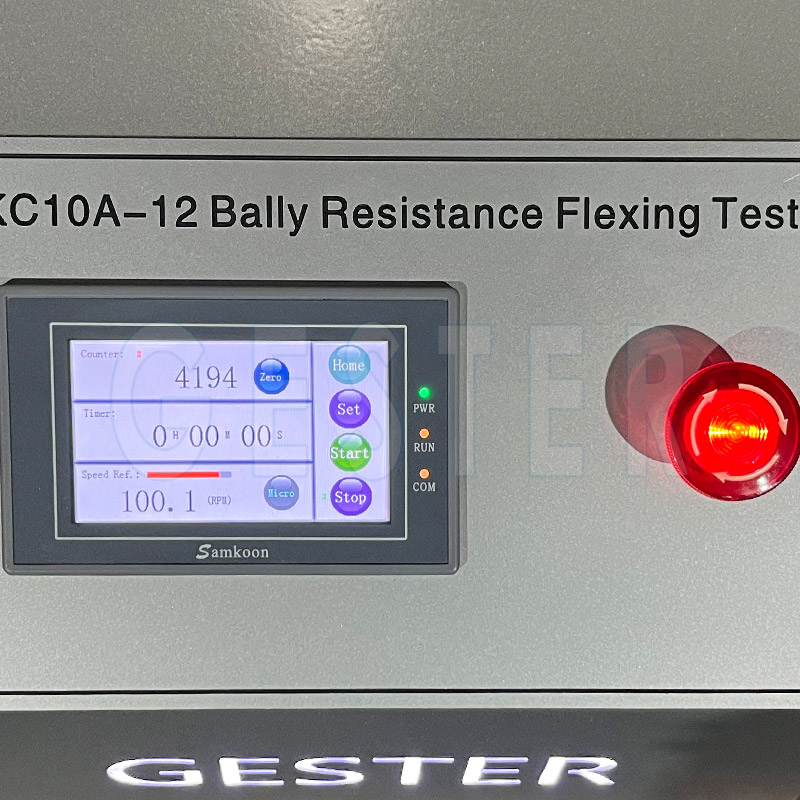

Bally Leather Flexing Tester to determine the resistance of a material to cracking or other types of failure at flexing creases. The method is applicable to all flexible materials and in particular leathers, coated fabrics and shoes. The method is applicable to all flexible materials and in particular leathers, coated fabrics and textiles used in footwear uppers.

2. Features

The test specimen is folded in half with one end secured in a clamp. It is then turned inside out, and the free end is secured in a second clamp positioned 90 degrees to the first. The first clamp oscillates repeatedly through a fixed angle at a defined rate, causing the specimen to flex.

3. Compliant Standards

Equipped with A type of upper grips.

SATRA TM 55; IULTCS/IUP 20-1; ISO 17694 ; EN 13512 ; EN344-1 section 5.13.1.3 and annex C; GB/T20991 section 6.6.2.8;

AS/NZS 2210.2 section 6.6.2.8; JIS-K6545; BS 3144 clause 13

Equipped with B type of upper grips.

ISO 32100 ; DIN53351; ISO5402-1; GE-24; ASTM D 6182; EN ISO 20344-2021 section 6.6.3