The main factors affecting color fastness to wet rubbing

1. fabric type, fabric structure

2. Pre-treatment of textiles, such as desizing, scouring, bleaching, mercerizing, etc.

3. Whether the selection of textile dyes and the control of process, temperature, time, etc. are strict

4. Whether the selection and use of additives are correct

5. Post-processing of textiles, etc.

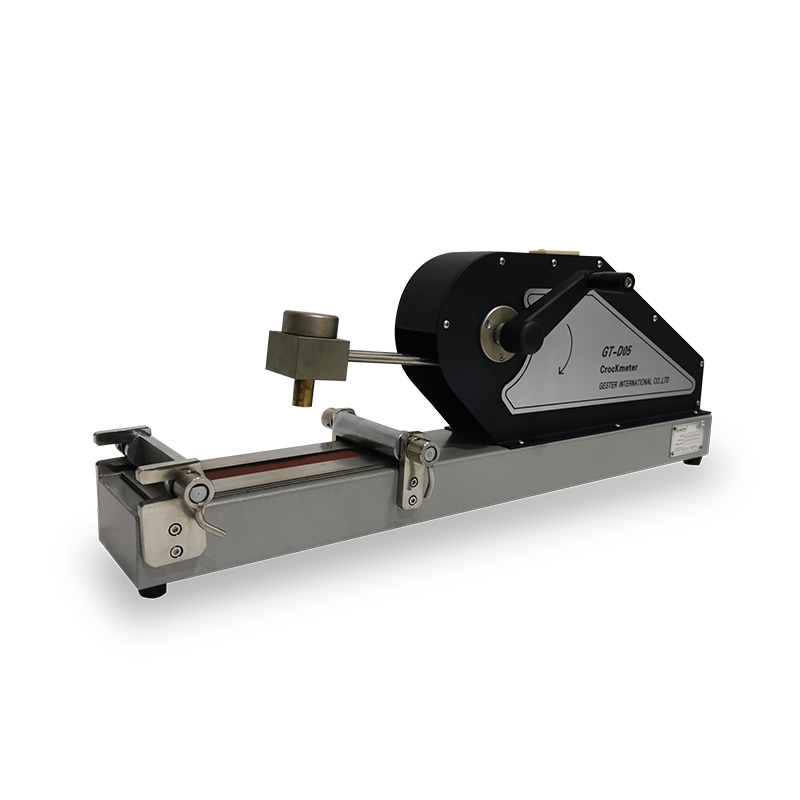

With the great R&D strength of products and great production capability, GESTER can provide high quality Manual Crock Meter Dry Wet rubbing fastness Tester GT-D05.GESTER collected some questions about color fastness to wet rubbing problems and how to solve them

Make improvements from the following points

1. According to the analysis of textile materials, general chemical fiber fabrics have better color fastness to wet rubbing than natural fabrics such as cotton, and thin fabrics are better than heavy fabrics. Therefore, in the processing of textiles, each process must be evenly processed to improve the absorbability of the fiber and the reactivity of the dye or the adsorption and fixation, so that the dye is fully dyed. In the process, strict control is required, and additives must be selected and used correctly. In order to improve the color fastness to wet rubbing of textile products, sufficient soaping can be carried out in the post-treatment of textiles. For example, the high temperature setting of polyester fiber after dyeing with disperse dyes causes the dye to migrate to the surface of the fiber, causing the rubbing fastness to decrease. In response to this situation, a reinforcing color agent or a smoothing agent can improve the color fastness to rubbing to a certain extent.

2. Crockmeter test When selecting dyes, select dyes with good promotion and levelness. Good promotion and levelness are conducive to the penetration and diffusion of dyes, which can improve wet rubbing fastness to a certain extent. The dye should have a certain water-soluble and direct, water-soluble group can not be too much, otherwise it will affect the wet rubbing fastness behind. And the directness should also choose medium as the best. The selected dye should not have too high directness, generally should be greater than 70%.

3. The color fastness to wet rubbing of natural fabrics such as cotton is relatively poor, so the grey cloth with uniform yarn count and smooth surface should be selected for cotton grey cloth. High-efficiency pre-treatment agent should be used if pretreatment is needed.

4. Use soft water or deionized water as much as possible for the dyeing water of reactive dyes, so as to reduce the influence of calcium and magnesium ions in the water on the dyes, thereby improving the fiber's absorption of dyes and making the dye fixation in the fiber molecules more stable.

5. Use high-efficiency fixing agent. The selected fixing agent should be able to link the dye and fiber to form a compound. When reacting with the dye, it can react and crosslink with the cellulose fiber, so that the dye and fiber can be tight and firm. The ground is connected together to strengthen the combination of dye and fiber, prevent the dye from falling off the fiber or migrating to the surface of the fiber, and avoiding the decrease of color fastness.

6. The use of special additives, such as darkening agent, dyeing fabric finishing, can reduce the amount of dye to obtain deep color effect, and improve the color fastness to wet friction.

7. Pay attention to the pH value of the cloth after dyeing. Generally speaking, the amount of alkali used in the dyeing process of deep colored cotton fabric is high, and then the washing, soaping and neutralization should be strengthened. Alkali can not be carried on the fabric, so as to avoid the hydrolysis of the dye after dyeing, resulting in the decrease of wet rubbing fastness. Usually the cloth pH value is controlled in 6.5-7.5, can not exceed 9 or less than 3。

8. Starting from the characteristics of the dyed cloth, finish the fabric, such as enzymatic polishing treatment, so as to increase the finish of the cloth, reduce the friction, so as to improve the color fastness to wet friction.

9. The floating color on the fiber is very unfavorable to the color fastness to wet friction. It is advisable to soap-cook the fabric dyed with deep color reactive dye twice, but too many soap-cook times will destroy the dye already dyed, resulting in bond breaking phenomenon, resulting in reduced effect. It has been tested that the wet rubbing fastness of dyed fabrics can reach grade 3 by washing them with anti-stain detergent (dosage 2-3g/L, treated at 95℃ for 10min). In the actual large-scale production, often occur many conditions, such as steam pressure fluctuation, so that the temperature is not high in the specified time; Stop vehicle operation error or sudden equipment failure, and make the scheduled program deviation, color difference after the addition of dye chemicals, and so on, resulting in color fastness difference (including cylinder difference). For some mechanical equipment and dye varieties, alkali and other chemical agents, in mass production to make the cleaning after dyeing is not very practical, so it should be reasonable choice.

10. It is difficult to remove the floating color after dyeing with reactive dyes. Therefore, after soaping, an appropriate color stripping agent can be used to remove the floating color, so that the fabric dye and fiber after the floating color can be removed. Form a complete body, thereby improving its wet rubbing color fastness.

Copyright © 2025 GESTER International Co.,Limited | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.