When you need to evaluate the degradation of materials after long-term exposure, are you still spending months or even years on natural weathering tests?

The UV accelerated weathering tester can show the results of years of material aging in days or weeks by simulating the damaging effects of sunlight, rain and dew.

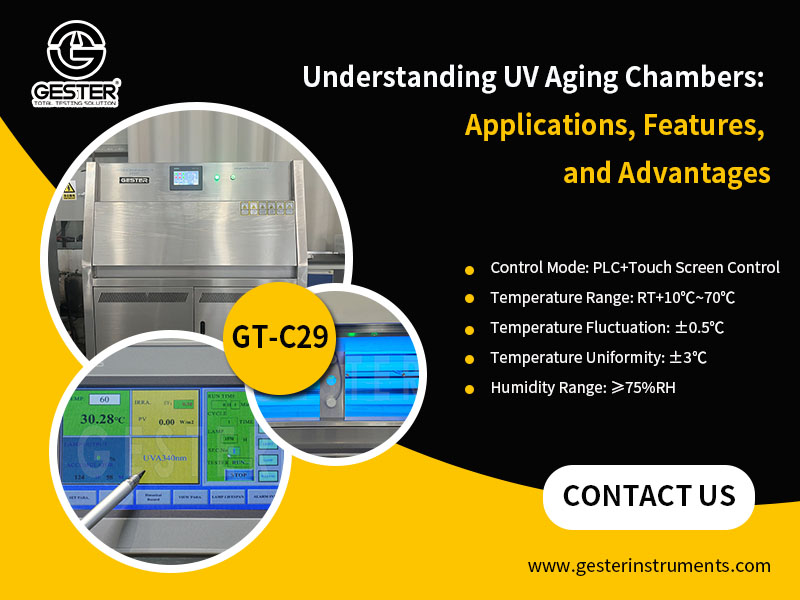

In this article, we will analyze how GT-C29 Intelligent UV Accelerated Aging Tester can provide efficient and reliable aging test for paint and coating, automotive industry, plastic products, wood products, glue and other industries through technological innovation.

GT-C29 Intelligent UV Accelerate Weathering Tester use UVA-340 fluoresvent UV lamp as light sources which can simulate the harm of sunshine, rain and dew The equipment operates by combining ultraviolet rays, rain, high temperature, condensation and darkness into a cycle, which repeats automatically. The operating principle of this machine is combining the ultraviolet rays, rain, high-temperature, condensation and darkness as a circulation an d repeat the circulation automatically. We can get the weathering test result of specimen by these circulations. The UV Accelerate Weathering Tester can reproduce the months and years harm in several days or weeks. The harm includes color fading, discoloring, chalkiness, cracking, muddy, bubble, embrittlement, intensity, recirculation, and darkness as a circulation an d repeat the circulation automatically. The harm includes color fading, discoloring, chalkiness, cracking, muddy, bubble, embrittlement, intensity, recession, oxidation etc.

Equipment appearance and structure design

1. The case is made from numerical control equipment,which is with advanced technology, smooth lines, beautifully designed.

2. Material of the cabinet is thickness 1.2mm, SUS304# advanced stainless steel.

3. The unit is mounted on high-quality PU casters for mobility

4. The specimen holders are constructed with stainless steel reinforced by aluminum alloy.

Temperature control and air circulation system

1. The chamber features a single-loop air circulation system, the imported axial fan enhances the air circulation ability of the light source and heating element, which significantly improves the temperature uniformity inside the test chamber.

2. The temperature inside the test chamber is measured by the sensor on the blackboard (fixed width 75㎜, height 100㎜, thickness 1.5㎜), which needs to be placed in the center area of the exposure test, and the thermometer measurement range is from 30 to 80°C with an error of ±1°C. The light and the condensation need to be carried out separately. Light exposure and condensation phases operate independently, and condensation is controlled by heating water temperature.

Light source system

1. Lamp: the dedicated ultraviolet, UVA-340 or UVB-313(option), 8 lamps, 4 on each side with a total of 2 sides,40W/1.

2. Lamp life: more than 1600h

3. Sample surfaces are positioned parallel to the UV irradiation plane.

Water circulation system

1. Water system: consumes approximately 8L of tap or distilled water daily.

2. Drainage utilizes a U-trap sediment collection system.

3. Spray system built-in automatic water spray device, water pressure adjustable.

Safety protection mechanism

The power supply adopts residual current circuit breaker control circuit, with functions of overload and short circuit alarm, over-temperature alarm and water shortage protection.

UV Aging Chamber has many advantages and is favored by various industries. Key factors contributing to its widespread adoption include:

Accelerated Aging Test:

It compresses months or years of environmental degradation into days or weeks, dramatically shortening R&D and QC cycles.

High accuracy and repeatability:

Precise temperature control and uniform UV irradiation ensure consistent test results.

Equipment durability:

SUS304 stainless steel cabinet and corrosion-resistant materials ensure long-term stable operation of the equipment in harsh environments.

Cost Effectiveness:

Low water consumption and energy-efficient operation significantly reduce operating costs.

Wide Compatibility:

Applicable to paint and coating, automotive industry, plastic products, wood products, glue and other materials testing needs.

Multiple Safety Guarantees:

Built-in alarms and protection mechanisms reduce operational risks during extended testing.

GT-C29 UV aging tester has become the preferred equipment for material durability assessment in various industries with its fast, accurate and reliable testing capability. Its rugged construction and precise control systems deliver a cost-effective, high-efficiency testing solution.