Analysis of the principle and characteristics of the thermal shock test chamber

by:GESTER Instruments

2021-07-03

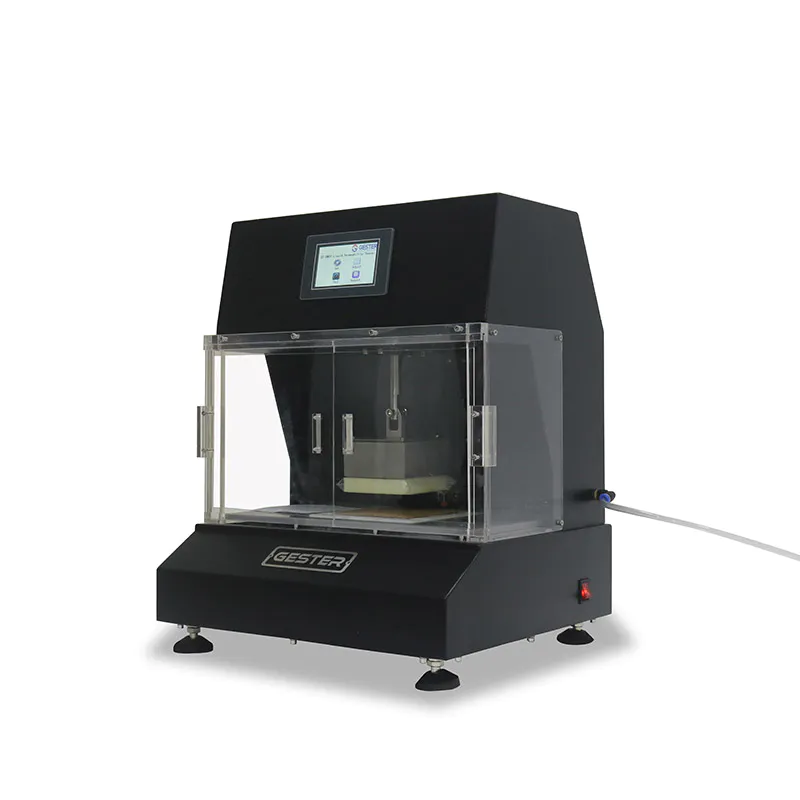

Principle: thermal shock test machine is used in electronic and electrical components, automation components, communication components, auto parts, metals, chemical materials, plastics and other industries, defense industry, aerospace, ordnance industry, BGA, PCB base board, electronic chip IC , The physical changes of semiconductor ceramics and polymer materials, the repeated resistance of the materials to high and low temperatures, and the chemical changes or physical damage of the product due to thermal expansion and contraction, can confirm the quality of the product, from precision IC to There is no need for an ideal testing tool for heavy mechanical components. Features of thermal shock tester: 1. The product has beautiful appearance, reasonable structure, advanced technology, exquisite material selection, simple and convenient operation performance and reliable equipment performance. The equipment is divided into three parts: high temperature box, low temperature box and test box. It adopts a unique thermal insulation structure and heat storage and cold storage effect. The test object is completely static during the test. The cold and hot air path switching method is used to introduce the cold and hot temperatures into the test area. The purpose of the thermal shock test. 2. The most advanced measuring device is adopted, and the controller adopts a large color LCD human-machine touch dialogue LCD human-machine interface controller, which is simple to operate, easy to learn, stable and reliable, and complete display in Chinese and English. The system operating status, execution and setting of the program curve. With 96 test specifications independently set, the impact time is 999 hours and 59 minutes, and the cycle period can be set from 1 to 999 times. It can realize the automatic operation of the refrigerator, and realize the automation to the greatest extent, reduce the workload of the operator, and can be automatic at any time Start and stop working; 3. There is a test hole with a diameter of 50mm on the left side of the box, which can be used for external power load wiring test components. It can independently set the functions of high temperature, low temperature and cold and heat shock conditions. When performing cold and heat shock conditions, you can choose two-slot or three-slot and cold punching and hot punching for the impact function, with high and low temperature The function of the test machine. 4. Equipped with fully automatic, high-precision system loop, any machine action, PLC lock processing, all adopt PID automatic calculation control, high temperature control accuracy. Advanced scientific air circulation circulation design, make the indoor temperature uniform, avoid any Dead corners; complete safety protection devices avoid any potential safety hazards and ensure the long-term reliability of the equipment. 5. The number of cycles and the number of defrosts can be set to automatically (manually) defrost. The air outlet is detected and controlled by the return air outlet sensor, The damper mechanism switching time is completed within 10 seconds, and the Bell brand thermal shock temperature recovery time is completed within 5 minutes. Status display and curve display during operation. When an abnormal situation occurs, the screen will automatically display the fault point and cause and provide troubleshooting methods. When the input power is found to be unstable, it has an emergency shutdown device. 6. The refrigeration system adopts the design of a cascade high-efficiency low-temperature circuit system, and the refrigeration unit adopts imported compressors from Europe and America, and adopts the green environmental protection (HFC) refrigerant R507, R23 with zero ozone coefficient. Super safety protection function: power overload protection , Leakage protection, control circuit overload, short-circuit protection, compressor protection, grounding protection, over-temperature protection, alarm sound prompts, etc. The main technical parameters of the thermal shock test machine: high and low temperature zone temperature range: [high temperature zone part: +80℃ to +200℃; low temperature zone part: -10℃ to -55℃] temperature test range: [high temperature: +60℃ To +150℃; “Low temperature: 0℃ to -40℃] “Control accuracy: [+(-)2℃] Resolution accuracy: [0.01℃] High temperature zone Heating time: [From normal temperature to 150℃, about 60 minutes] Low temperature zone Cooling time: [From normal temperature to -40℃, about 80 minutes] Test area temperature recovery time: [3-5 minutes]

is frequently used by people in daily life since it can improve tensile tester manufacturers and tensile tester manufacturers.

GESTER International Co.,Limited has a wide variation of including tensile tester manufacturers, tensile tester manufacturers and tensile tester manufacturers, etc.

You can get more information from GESTER Instruments for on sale. welcome to visit us and send your inquiry!

is frequently used by people in daily life since it can improve tensile tester manufacturers and tensile tester manufacturers.

GESTER International Co.,Limited has a wide variation of including tensile tester manufacturers, tensile tester manufacturers and tensile tester manufacturers, etc.

You can get more information from GESTER Instruments for on sale. welcome to visit us and send your inquiry!

Custom message