Zippers are exposed to constant use, wear, and stress. A defective zipper can compromise the quality and usability of a product, leading to dissatisfied customers or increased product returns. Zipper strength testing evaluates factors such as connector failure, fluff, wear, or joint loosening through a controlled and repeatable process. This ensures that zippers meet quality standards and can withstand daily usage.

The zipper fatigue tester GT-C39A is designed for comprehensive testing of zippers in a continuous back-and-forth motion. Its advanced features and user-friendly interface make it an ideal tool for manufacturers and quality control teams.

Key Features:

Effortless Operation: Designed with simplicity in mind, the zipper fatigue tester GT-C39A is easy to use, even for first-time operators.

Automatic Counting and Stopping: The Slide Fasteners Reciprocating Tester counts each test cycle automatically and stops once the test parameters are met or the zipper fails.

Follow these detailed steps to perform a successful zipper strength test:

1. Setting Up the zipper fatigue tester

Connect the zipper fatigue tester to an AC220V power supply.

Turn on the power switch to activate the machine.

2. Installing the Zipper Sample

Take a zipper and select an appropriate zipper head fixing piece.

Secure the zipper handle in the fixture by locking it with a wrench.

Thread the tail of the zipper through the upper fixture, ensuring it is not locked tightly at this stage.

3. Adjusting Fixtures

Place a 60° angle gauge between the fixtures and ensure they are aligned.

Lock the zipper into place using the fixtures, then remove the angle gauge.

For the upper fixture, lift the zipper tail upwards to align with the reference line before locking it tightly.

For the left and right fixtures, adjust them to position 5mm from the zipper’s edge and lock them securely.

4. Applying Tension

Loosen the upper and lower locking nuts on the tension gauge.

Pull the gauge downward until the scale pointer reaches 1kg, then tighten the locking nuts.

Repeat this process for the other three gauges.

5. Checking for Smooth Operation

Rotate the manual knob to verify that the zipper head moves freely along the track.

6. Configuring Parameters and Starting the Test

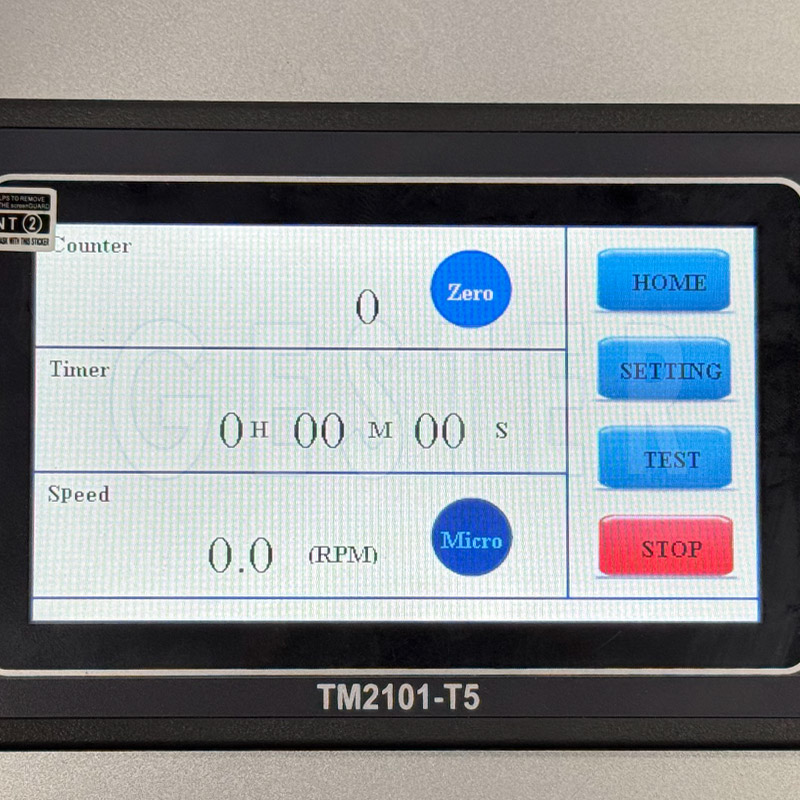

Switch the zipper fatigue testerinterface to English by clicking “SET.”

Select the desired zipper testing mode (e.g., “Counter” for counting cycles) and set the number of cycles (e.g., 100).

Click “Return,” “Zero,” and then “Start” to begin the test.

The Zipper Testing Machine will automatically stop after the preset cycles or if the zipper fails during the test.

The results of the zipper strength test provide valuable insights:

Pass: The zipper completes the preset number of cycles without any noticeable issues such as wear, joint loosening, or fluff.

Fail: The zipper fails to complete the test due to breakage, excessive wear, or loss of functionality.

These results help manufacturers determine if their zippers meet industry standards and consumer expectations.

Investing in proper zipper strength testing offers numerous benefits:

Improved Product Quality: Identifies potential weaknesses before products reach customers.

Cost Savings: Reduces returns and warranty claims by addressing issues early.

Enhanced Reputation: Demonstrates a commitment to delivering reliable products.

Compliance Assurance: Ensures zippers meet international quality and safety standards.

Zipper strength testing is a vital process for any manufacturer aiming to produce high-quality, durable products. The GT-C39A Zipper Testing Machine simplifies this task with its precise design and automated functionality. By following this guide, you can efficiently assess the resilience of zippers, ensuring they meet the highest standards and satisfy consumer demands.

Whether you’re new to zipper testing or looking to upgrade your quality assurance processes, the zipper fatigue tester GT-C39A offers a reliable and efficient solution. Don’t compromise on quality—test your zippers today and ensure lasting performance.

Copyright © 2025 GESTER International Co.,Limited | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.