Aging test and environmental test methods for instruments

by:GESTER Instruments

2021-07-07

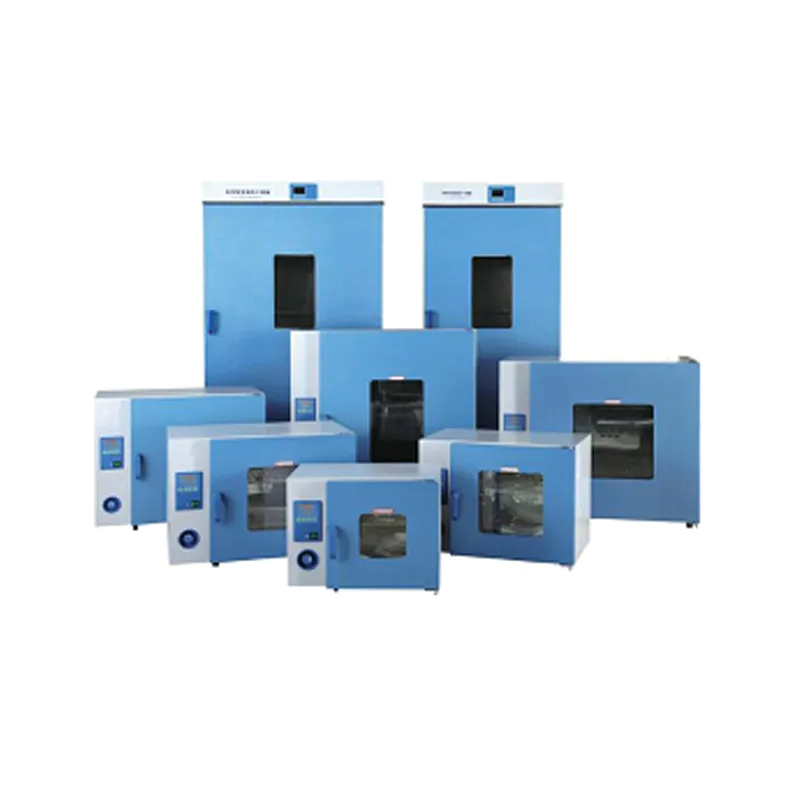

The production of many companies cannot do without the help of instruments, but after the instruments are used for a certain period of time, the products will deteriorate. Therefore, it is necessary to carry out aging test and environmental test. It can detect a potential failure of the early instrument, especially the common failure that can be found. Therefore, the same instrument and equipment can be restored by modifying the circuit and method in the early stage, which helps to improve the durability of the equipment. Sex and reliability. Next, Shanghai Qianshi will introduce the aging test and environmental test methods of instruments and meters. What is the aging test of the instrument? During the general aging test, some instruments and meters are energized and operated continuously for a long time, and their average trouble-free working time is measured. The fault characteristics of these instruments and meters are analyzed and summarized, and their common problems are found to be solved. How long is this 'long duration'? Generally 24 hours or 48 hours, of course, it can also be 1 hour or 0 hours. This is the pursuit of quality and cost requirements. Aging test is also called baking machine or burn-in machine, which means to test it harshly or 'try to burn it'. Only those products that have been tortured and survived are excellent products. Reputable companies will only sell these to user. Every piece of equipment of our Wuhan Guoliang Instruments has undergone an extremely strict aging test process to ensure that the equipment that reaches the user's hands is of extremely high quality. What is the environmental test of the instrument? Environmental test is generally to determine the specific test content according to the working environment of the instrument and meter, and conduct the test in accordance with the method prescribed by the country. Environmental tests are generally carried out on samples of products. Common environmental test contents and methods are as follows: (1) Temperature test Temperature test is used to check the influence of temperature environment on instruments and meters, and to determine the adaptability of instruments and meters to work and storage under high and low temperature conditions It includes high temperature and low temperature load test, high temperature and low temperature storage test. High temperature test is used to check the influence of high temperature environment on instruments and meters, and to determine the adaptability of instruments and meters to work and store under high temperature conditions. It includes high temperature load test and high temperature storage test. Low temperature test is used to check the influence of low temperature environment on instruments and meters, and to determine the adaptability of instruments and meters to work and store under high temperature conditions. It includes low temperature load test and low temperature storage test. The temperature load test is to put the instrument in the temperature test box under the condition of unpacked, unpowered and normal working position, and carry out the test of the upper and lower limit working temperature for rated use. (2) Vibration and shock test Vibration test checks the stability of instruments and meters subjected to vibration. The method is to fix the sample on the vibration table, and test it through various vibration environments such as simulating fixed frequency (50HZ) and frequency conversion (5-2KHZ). After a cycle is completed within a certain frequency range, the inspection shall be carried out according to the regulations. For example, the SF6 gas trace moisture analyzer must avoid vibration and shock. Experiments have proved that because the polymer film capacitive humidity sensor is easily damaged by impact, the SF6 gas trace moisture analyzer cannot work. Impact test is used to check the adaptability of instruments to withstand non-repetitive mechanical shocks. The method is to fix the sample instrument or meter on the test bench with a certain acceleration and frequency, and impact the sample several times in different directions. After the impact test, check whether the main technical indicators still meet the requirements and whether there is mechanical damage. (3) Transportation test The transportation test is to check the packaging, storage, and transportation capabilities of the instrument. Method The sample is fixed on the test bench or can be installed on a truck to run. The specific method is in accordance with the relevant standards. The transportation test is based on the main technical indicators and performance of the prescribed detector. In short, both the aging test and the environmental test are to check the reliability of the product. Generally, immediately after the processing process, there will be aging tests and environmental tests on the circuit boards and components.

Every day of the year, there is some city or town in the world that is changing over to for tensile tester manufacturers.

GESTER International Co.,Limited works hard to enhance continuously our reputation for accessibility, professionalism, performance, and the depth and quality of our long-term consultative relationships with clients.

The only cardinal rule with adding animation is to keep high-quality on textile testing equipment.

Every day of the year, there is some city or town in the world that is changing over to for tensile tester manufacturers.

GESTER International Co.,Limited works hard to enhance continuously our reputation for accessibility, professionalism, performance, and the depth and quality of our long-term consultative relationships with clients.

The only cardinal rule with adding animation is to keep high-quality on textile testing equipment.

Custom message