Leather Physical Properties Testing Guide

Physical property tests

1. Tensile strength: Tests the leather's ability to resist breaking under tension when subjected to stretching.

2. Tear strength: Assesses the leather's ability to resist tearing when subjected to tearing force.

3. Abrasion resistance: Tests the leather's abrasion resistance by simulating friction encountered during daily use.

4. Thickness: Measures the thickness of the leather to ensure it meets specific specification requirements.

5. Water vapour permeability: The water vapour permeability of leather depends on its breathability and is also influenced by the leather's own moisture absorption capacity.

6. Water resistance: The leather's ability to resist water absorption, water penetration, and being wetted by water.

7. Shrinkage temperature: The shrinkage temperature of leather is a key parameter indicating the degree of tanning and hydrothermal stability the degree of tanning and moisture-heat stability of leather.

8. Colour fastness to friction: The extent to which the colour and coating of the leather surface change or transfer due to friction.

9. Bending strength: The number of times leather can be repeatedly bent without causing surface damage.

Testing Scope

Leather testing covers natural leather, synthetic leather, and various finished and semi-finished products made from them. The following are common testing scopes:

Natural leather: animal leather types such as cowhide, sheepskin, pigskin, and horsehide.

Synthetic leather: including PU/PVC artificial leather and other synthetic alternatives

Leather products: leather for footwear, clothing, handbags, furniture, automotive interiors, etc.

Leather semi-finished products: including blue wet leather, chrome-tanned leather, vegetable-tanned leather, etc., at various stages of processing.

Whether for industrial production or end-consumer use, the scope of leather testing can be customised according to specific requirements.

Testing Equipment

Leather testing relies on high-precision equipment. The following are several commonly used testing instruments:

1. Tensile:

Universal Testing Machine GT-K01

This universal tensile tester is designed for conducting tensile and other tests for leather. It is a basic equipment of quality control, receiving inspection, physical test, mechanics research, material development.

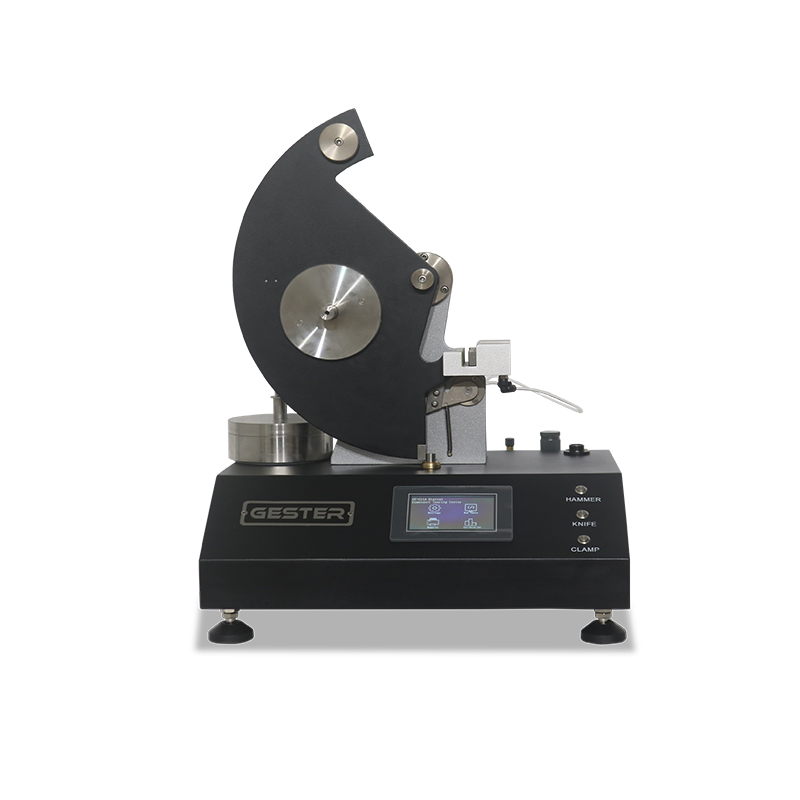

2. Tearing:

Electronic Elmendorf Tearing Strength Tester GT-C11A

This Elmendorf Tearing Tester is designed for tearing resistance of textile, non-woven fabric, paper, paper board, thin film, ventilation tape, metal sheet material and etc.

3. Abrasion:

IULTCS & Veslic Leather Abrasion Tester GT-KC01-1

IULTCS & Veslic Leather Abrasion Tester is used for color fastness testing of leather, plastic and textile. Under the specified pressure, let white wool felt to do reciprocating abrasion to the surface of dye sample. After a specified count, to assess the color fastness of sample by checking the color change and fading of sample and the discoloration of white wool felt. It can be used for dry abrasion testing and wet abrasion test.

Leather Reciprocation Abrasion Tester GT-KC30

This machine is used to determine the abrasion resistance of the sole leather. It is applicable to sole leather for footwear application.

4. Thickness:

Thickness Gauge ( Leather ) GT-KD07

The thickness gauge is used to measure the thickness of vulcanized rubber and leather products. Clamp specimen between up and down parallel round plates. The pointed graduation is the thickness.

5. Water Vapor Permeability

Leather Water Vapor Permeability Tester KC51D

To determine the permeability of leather to water vapor by measuring the rate at which water vapor passes through a test specimen.

6. Water Penetration:

Leather BALLY Water Penetration Testing Machine GT-KC06A

Bally Waterproofness Tester designed for assessing the water resistance of footwear upper materials, including leather, artificial leather, and fabric. This state-of-the-art tester is essential for determining the material's ability to resist water penetration during flexing, ensuring its suitability for various applications.

7. Shrinkage Temperature

Leather Shrinkage Temperature Tester GT-KC23

The Leather shrinkage temperature tester is mainly used to determine the shrinkage temperature of leather and fur. The specimen is heated at a specified rate in water until it is shrunk considerably.

8. Colour Fastness

AATCC Standards Electronic Crockmeter GT-D04

Electronic Crockmeter is used to determine the colour fastness of textiles to dry or wet rubbing. A pinned acrylic sample holder ensures rapid sample mounting and repeatability of results.

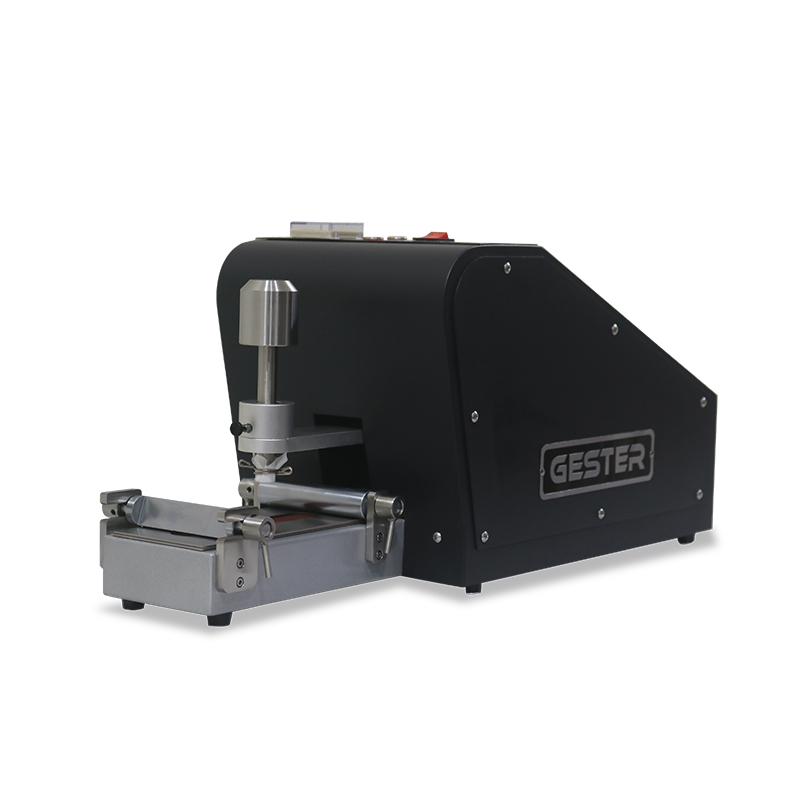

9. Flexing

Bally Leather Flexing Tester GT-KC10A

This Bally resistance flexing tester is used to determine the resistance of a material to cracking or other types of failure at flexing creases. The method is applicable to all flexible materials and in particular leathers, coated fabrics and textiles used in footwear uppers.

Copyright © 2025 GESTER International Co.,Limited | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.