How to Know the Fabric Shrinkage Test for Your Projects

Fabric shrinkage is a natural phenomenon. It can significantly affect the fit, appearance and life of a garment.

Fabrics are composed of fibers, and when fibers absorb water, swelling occurs with increased diameter and potential longitudinal expansion. The difference in length between the fabric before and after it has been in the water and the percentage of its original length is usually called the shrinkage rate. The stronger the water absorption capacity, the more intense swelling, the higher the shrinkage rate, the poorer the dimensional stability of the fabric.

Understanding fabric shrinkage and conducting shrinkage tests are critical steps in ensuring fabric quality and durability. In this article, we provide you with a complete guide to fabric shrinkage testing

Fabric shrinkage occurs when the fabric is exposed to water and the fibres themselves dissolve, shortening the length of the fabric further. Fabrics with different weave shrinkage rates have different magnitudes of shrinkage. Fabric structure and weaving tension of the fabric itself is different, the weaving shrinkage rate is different. Lower weaving tension results in looser fabric structure with higher weaving shrinkage, leading to less post-wash shrinkage, the fabric shrinkage rate is small; weaving tension is large, the fabric is loose and thin, weaving shrinkage rate is small, the fabric shrinkage rate is large.

● Raw material: The shrinkage rate of fabric is different depending on the raw material. Generally speaking, fibres with high hygroscopicity will swell after being immersed in water, increase in diameter and shorten in length, so the shrinkage rate will be large. For example, the water absorption rate of viscose fibre is as high as 13%, while the moisture absorption of synthetic fabrics is poor, and their shrinkage rate is small.

● Density: the density of the fabric is different, the shrinkage rate is also different. If the density of the warp and weft is similar, the warp and weft shrinkage rate is also close. Warp density of the fabric, the warp shrinkage is large, on the contrary, the weft density is greater than the warp density of the fabric, the weft shrinkage is also large.

● Yarn thickness: fabric yarn thickness is different, shrinkage rate is also different. Fabrics with coarse yarns exhibit higher shrinkage rates, fine yarn fabric shrinkage rate is small.

● Production process: fabric production process is different, shrinkage rate is also different. Generally speaking, fabrics in the weaving and dyeing and finishing process, Repeated fiber stretching during prolonged processing under higher tension results in greater fabric shrinkage, processing time is long, the fabric shrinkage rate of the larger applied tension is large, and vice versa is small.

● Fibre composition: natural plant fibres (e.g. cotton, linen) and plant regenerated fibres (e.g. viscose) are prone to moisture absorption and expansion compared to synthetic fibres (e.g. polyester, acrylic), so the shrinkage rate is larger, whereas wool is prone to felting due to the scaled structure on the surface of the fibres, which affects its dimensional stability.

● Fabric structure: In general, the dimensional stability of woven fabrics is better than that of knitted fabrics; the dimensional stability of high-density fabrics is better than that of low-density ones. In woven fabrics, the general shrinkage rate of plain fabrics is smaller than that of flannel fabrics; and in knitted fabrics, the shrinkage rate of flat needle organisation is smaller than that of ribbed fabrics.

● Production and processing: As fabrics are inevitably stretched by machines during the dyeing, printing and finishing processes, there is tension present on the fabrics. However, it is easy to release the tension when the fabric meets water, so we will find the fabric shrinking after washing. In the actual process, we generally use pre-shrinkage to solve this problem.

● Wash care process: Wash care includes washing, drying and ironing, and each of these three steps will affect the shrinkage of the fabric. For example, the dimensional stability of a hand-washed sample is better than that of a machine-washed sample, and the temperature at which it is washed also affects its dimensional stability. In general, the higher the temperature, the worse the stability.

Fabric Shrinkage Tests are used to measure and evaluate the dimensional changes that occur in fabrics after washing, drying or heat exposure. These tests help to understand the potential shrinkage of fabrics and to make informed decisions about fabric selection, sizing and care.

Fabric shrinkage tests are usually conducted according to recognised industry standards. Some common standards for fabric shrinkage testing include:

GB/T8629, GB/T8630, ISO6330/5077, FZ/T70009, BS4923, EN25077/26330, JIS L1909, IWSTM31,ISO19954,

SATRA TM158

In fabric shrinkage testing, a common test method is the use of Wascator Shrinkage Tester. It is used to evaluate the dimensional change and shrinkage of fabrics.

Fabric Shrinkage tester

Accelerated washing apparatus for knitted and woven fabrics to assess shrinkage in accordance with international test methods. Also used for assessing fabric stability, color fastness, finish durability, spirality and pilling to washing.

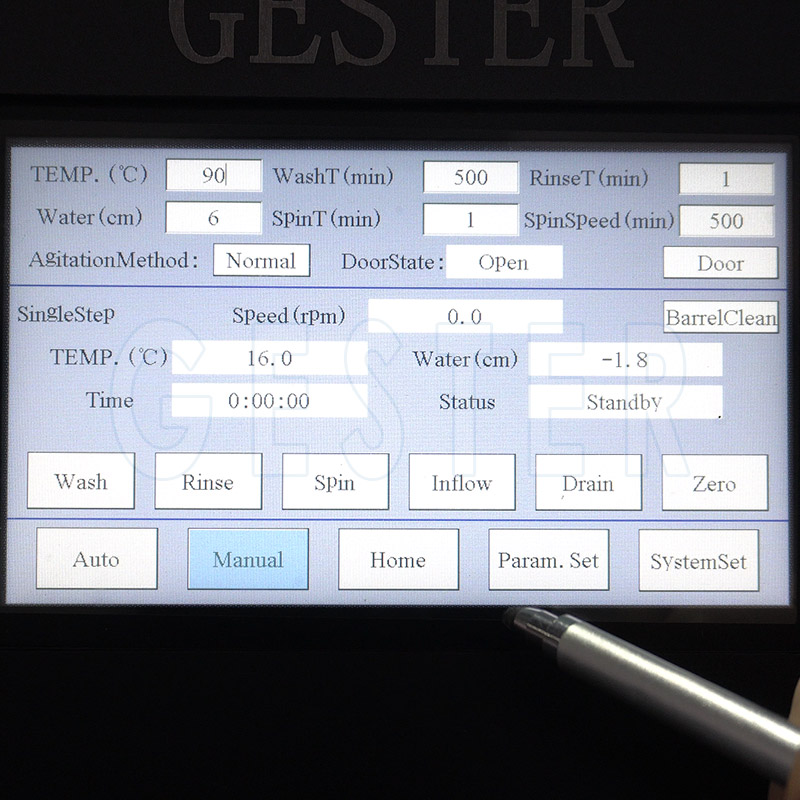

Adjust Settings: Set parameters such as water temperature, wash time, and agitation speed. Set these parameters accordingly to the instructions provided by the manufacturer or as specified in the test standard.

Fabric shrinkage can significantly affect the fit and quality of garments. Performing a fabric shrinkage test is critical for manufacturers, designers and consumers to understand potential changes in size after washing or heat exposure.

Using the Automatic Shrinkage Tester can help you better control fabric shrinkage and avoid sizing problems in garment design and production.