Introduction

Fabrics during use are subjected to light, washing, ironing, perspiration, friction, and chemical exposure. some printed and dyed textiles are also subjected to special finishing processes, such as resin finishing, flame retardant finishing, sand washing, brushing, etc., which requires printed and dyed textiles to maintain a certain degree of relative fastness to the color and luster.

Color fastness refers to a product's resistance to washing, friction, and other environmental factors.

Color fastness is good and poor, Substandard color fastness may pose health risks as, poor color fastness of the product in the wearing process, encounter rain, sweat will cause the pigment on the fabric to fall off and discoloration, the dye molecules and heavy metal ions, etc. may be absorbed by the human body through the skin and endanger the health of the human skin, on the other hand, it will also affect the wearer's other garments to be stained with colors, or with other clothing when washing dirty other Clothing. Because of the great difference in the conditions and requirements of the fabrics during processing and use, the following color fastness tests are available.

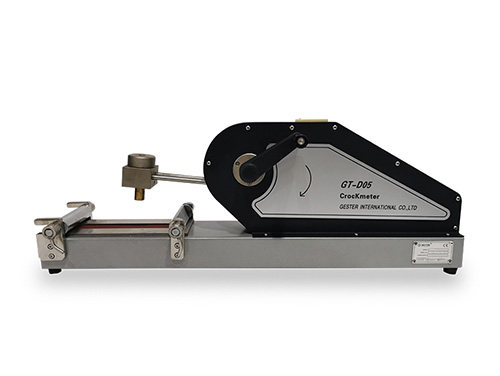

Color fastness to rubbing refers to the degree to which the color of a printed fabric remains firm under rubbing. The color fastness of colored materials to rubbing depends on two main factors.

Crockmeter to determine the colour fastness of textiles to dry or wet rubbing. A pinned acrylic sample holder ensures rapid sample mounting and repeatability of results.

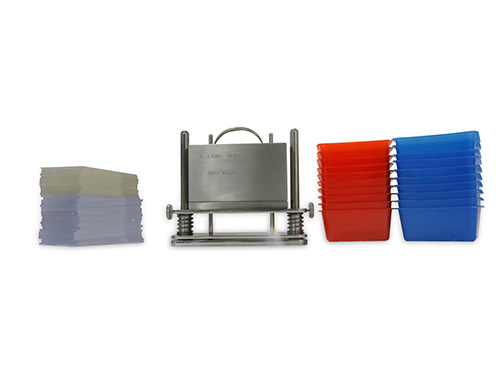

Color fastness to perspiration measures the ability of a printed textile to resist perspiration. Researchers use it primarily to test colored summer garments that come into regular contact with human skin.

The specimen is sewn together with a standard appliqué fabric, treated in a sweat solution, clamped to a color fastness to perspiration tester, placed in an oven at a constant temperature, then dried, and rated with a grey card to obtain the test results. Different test methods have different ratios of perspiration solution, different specimen sizes, different test temperatures and times.

Perspiration Testerapply for testing perspiration resistance color fastness of all kinds of textile materials & dyeing, colorful textile and test for their perspiration resistance, waterproof, seawater resistance, saliva resistance, chlorine bleach resistance, etamsylate resistance and other performance.

Color Fastness to Washing Measures the ability of textiles to resist fading when washed. It tests printed and dyed fabrics. It is a key quality measure for most of these textiles.

Washing Color Fastness Testerapply to test dyeing textile color fastness changing degree after washing, it not only do washing color fastness and also dry washing color fastness test.

Color fastness to light is the ability of a textile to resist fading when exposed to daylight or artificial light sources.

1. Colorfastness to Ozone GT-D01B

It is intended for assessing the Ozone resistance of color of textiles of all kinds and in all forms when exposed to atmosphere with certain temperature and humidity.

2. Suntest & Xenon Arc Tester

The Suntest & Xenon Arc Testers is a powerful Xenon Instrument for conducting accelerated tests of light fastness and photo stability tests.

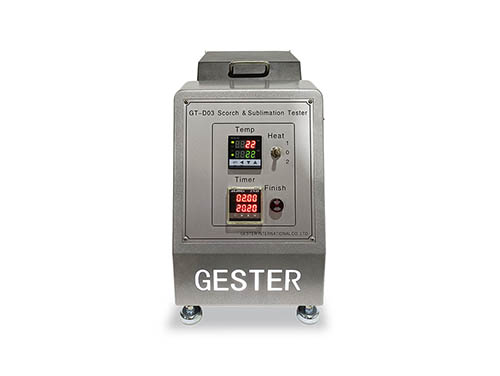

This is the degree of heat sublimation dyed fabrics experience in storage.

This Scorch & Sublimation Tester GT-D03 apply to textile assist color change or transfer capacity under heating condition, simulate textile being ironing and under high temperature & humidity dyeing color fastness to sublimation degree in daily life.

Color fastness characterizes a textile's ability to maintain its original hue despite environmental stresses. Users can carry out color fastness tests according to their needs.