A brief analysis of the test method for leather water and oil resistance

by:GESTER Instruments

2022-08-09

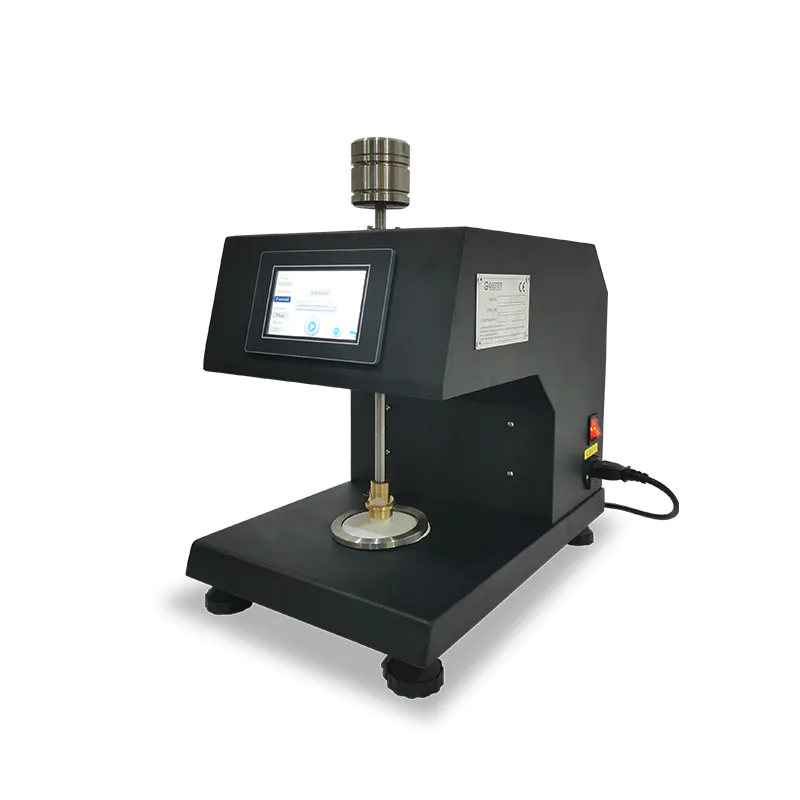

Grease has a certain solubility for leather. At the same time, as a substance with strong viscosity, it is a big problem in the washing process. This article focuses on the compatibility of oil with leather. Static water absorption method: This method is the standard method specified in ISO 2417:2016: put the kuble dish part A on the bottom and part B on the top and add distilled or deionized water at a fixed temperature; put the leather sample in the kuble dish Part B and record its scale value, tilt the Cube to make the sample completely immersed in distilled or deionized water; after the sample is immersed for a specified time, lift part B of the Cube to let all water flow into Part A to read the sample. Scale value; compares the water repellency of leather by calculating the amount of water absorbed. Usually, when the leather expands and contracts by 15% within 6 to 24 hours and the water absorption rate is less than 20%, it means that the leather has good water resistance. The simplified test method is (immersion method): weigh a leather sample of a fixed size and then immerse it in distilled water for 2 hours, take out the leather sample and wipe off the water on the surface of the leather sample with filter paper, weigh its weight, and measure the weight before and after the leather soaking. The water absorption rate (mass percentage) of the leather is calculated from the change to evaluate its waterproof performance. Maeser-Tests: Maeser-Tests is the primary testing method in North America. This method is a method developed by the Physical Testing Committee of the International Federation of Leather Technologists and Chemists: Place the leather sample with iron sheets and iron balls on the surface in the sink, and put water under the leather sample, install it and start the resistance The zigzag tester performs the zigzag test, through the conductivity of iron and the conductivity of water, when the current is detected, the number of zigzags is recorded, and the leather at this time is permeable to water. Water penetration (bending times) and dynamic water absorption (mass fraction) determine the waterproof performance of leather samples. The qualified bending times of leather samples are:>15,000 times water impermeability. Bally Penetration Testing: Bally Penetration Testing is the main testing method in Europe. This method is mainly used to test the dynamic waterproof performance of leather straps. The testing equipment is a water penetration tester (Swiss BALLY). During the test, the leather sample is fixed in a water bath, stretched its length, and the time when water penetrates is recorded, and the dynamic water penetration time is recorded. (minutes), calculate the water absorption rate (%) when permeable and the water absorption rate (%) at the specified tortuosity time. This test method was developed by the Physical Testing Committee of the International Federation of Leather Technologists and Chemists. Water repellency - drop test method: This method is ISO 23232:2009 and AATCC193-2009 American National Standard of the American Association of Chemists and Dyers for the determination of the water repellency of textile fibers. According to the surface tension of the test reagent solution (isopropanol aqueous solution of different volume fractions), it is divided into 0-10 grades. The test reagent solution with different surface tension is dropped on the surface of the leather sample (the spacing is 5mm), when a certain The test solution of one grade cannot wet the surface of the leather sample (by observing the surface morphology of the test droplet and its contact angle), it indicates that the surface tension of the leather is less than the surface tension of the test solution, and it passes the test of this grade; replace it with a higher grade The test solution is tested until the leather surface is wetted (according to the surface morphology of the droplet and its contact angle), and the final passing grade is selected as the waterproof grade of the fiber. Spray method: This method is ISO 4920:2012 and AATCC22-2014 American National Standard of the American Association of Chemists and Dyeers to determine the water resistance of textile fibers. The test method: spray 250ml of distilled water from a nozzle fixed at a certain height on the The surface of the fiber sample, and the nozzle of the nozzle is 45 mm from the surface of the sample.°By comparing the water trace pattern left by the fiber sample after spraying with the legend of the standard sample card, the waterproof level of the fiber sample can be measured. Ups and downs method: The ups and downs method is to use the relationship between the critical surface tension and waterproof performance to evaluate the waterproof level of leather by the size of the critical surface tension. The multiple surfaces of 2mm leather particles are used to characterize the water repellency of the leather surface, which is widely used in the Japanese textile industry. Oil repellency-droplet test method: This method is ISO 14119:2010 and AATCC118-2013 American National Standard of the American Association of Chemists and Dyers for the determination of oil repellency of textile fibers. Leather can be used for reference. Since different types of oil analytical reagents have different surface tensions, they are divided into 1 to 8 grades according to the surface tension. Different grades of oil analytical pure reagents are dropped on the surface of the leather sample at a distance of 5mm. If the analytically pure reagent cannot wet the surface of the leather sample (according to the surface morphology of the droplet and its contact angle), it means that the surface tension of the leather is less than that of the test reagent, and it passes the test at this level; then use a higher-level reagent Test until the surface of the fiber is wet (according to the surface morphology of the droplet and its contact angle), then select the last grade passed as the oil-proof grade of the fiber.

GESTER International Co.,Limited specializes in undertaking corporate offers to cater the needs of different companies.

We are dedicated to providing you with more than just customer service by utilizing our qualified team who pride themselves on meeting and exceeding customer's needs. We also have ell-equipped plantin China with advanced facilities to manufacture tensile tester manufacturers textile testing equipment products according to customers requirements. Welcome to send your enquiry and visit our factory. Our website is GESTER Instruments.

Getting textile testing equipment from an idea to production is a complex process. It involves significant research, time, planning and patience. But with the right information, the right resources and the right product, it's possible.

give you an additional tensile tester manufacturers option for your tensile tester manufacturers, whether it being a tensile tester manufacturers, tensile tester manufacturers or tensile tester manufacturers. Go and get more info at GESTER Instruments.

GESTER International Co.,Limited specializes in undertaking corporate offers to cater the needs of different companies.

We are dedicated to providing you with more than just customer service by utilizing our qualified team who pride themselves on meeting and exceeding customer's needs. We also have ell-equipped plantin China with advanced facilities to manufacture tensile tester manufacturers textile testing equipment products according to customers requirements. Welcome to send your enquiry and visit our factory. Our website is GESTER Instruments.

Getting textile testing equipment from an idea to production is a complex process. It involves significant research, time, planning and patience. But with the right information, the right resources and the right product, it's possible.

give you an additional tensile tester manufacturers option for your tensile tester manufacturers, whether it being a tensile tester manufacturers, tensile tester manufacturers or tensile tester manufacturers. Go and get more info at GESTER Instruments.

Custom message