China's filter material performance testing and standard development process

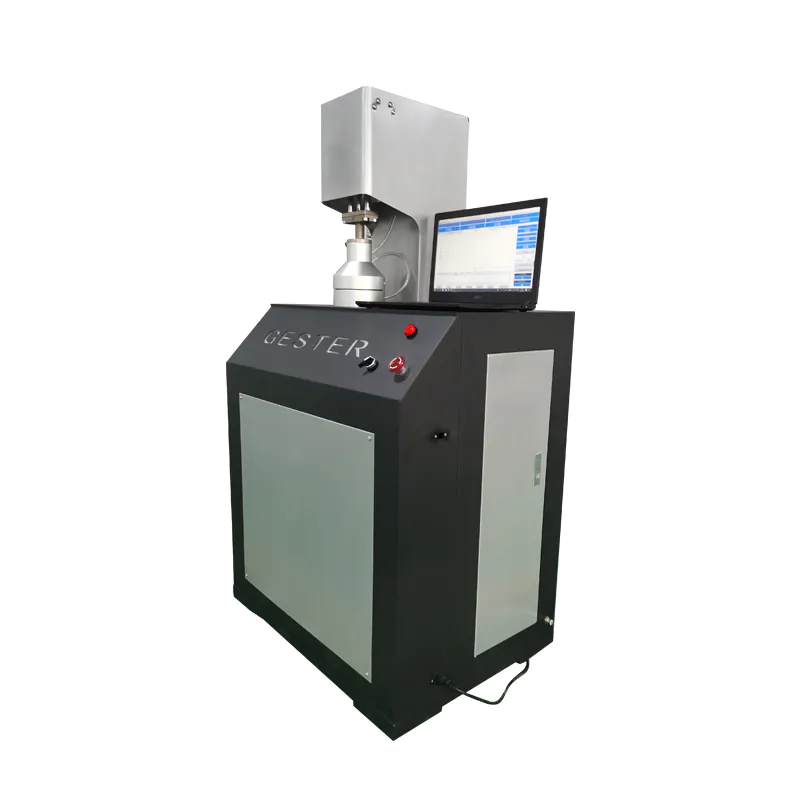

by:GESTER Instruments

2021-06-20

The filter material performance test method standard is different from the filter performance test method standard. The filter performance test must meet the characteristic requirements of the fluid system (or working position) where it is located, and the filter material must meet the filter performance requirements at the same time, It is also necessary to meet the manufacturability requirements and physical and chemical performance requirements in the filter production process to achieve a long life, good workmanship, reliable strength and high efficiency in blocking small-sized particles. Among the many performances of filter materials, some are similar to the performance of filters, such as 'filtration accuracyFeatures to test its performance, this is the so-called 'filter material performance test method standard'; there are some physical and chemical properties, such as flexural strength, bursting strength, compatibility with working fluid, etc., which are beneficial to processing Relevant regulations on craftsmanship, finished product quality and life span. 1. The current status of the main performance definitions and test methods of foreign oil filter materials. The definition of filtration accuracy of modern oil filters has gradually accepted the filtration characteristics evaluation method of hydraulic filters, that is, the filtration process of oil containing polluting particles is based on particles of a certain size. The ratio (efficiency) of the quantity before and after filtration determines the 'filtration accuracy'. This method is called the 'multiple pass test method'. The multiple-pass test method was originally developed by Dr. Fitch from the Fluid Power Research Center of Oklahoma State University, and later became the American National Standard. It was included in the international standard in 1981. It is a test method for hydraulic technology to assess the filter performance of the filter element. Now all filter elements used in industrial oil system and engineering vehicle oil systems are gradually adopting this standard, and the performance assessment of filter materials is also used abroad. The assessment method is: Put the test powder in the test system as required, and the contaminated oil will pass through the tested filter element (or filter material) to establish a pressure difference in this test section, and sample and test before and after the filter element at several pressure difference points. The number of particles of at least 6 different sizes before and after filtration, and then the number of particles before filtration is divided by the number of particles of the corresponding size after filtration to obtain the filtration ratio (β) (refer to Figure 1). During the process of establishing the filter element pressure difference, the reduced number of particles in the polluted liquid of the test system will be slowly provided by another dirt injection system (high-concentration polluted liquid). The test will stop when the pressure difference reaches the rated value. If there is a value of 75 in the filtration ratio β value of the 6 size particles, the accuracy value of the tested filter element is determined as the size. The multiple-pass test method is different from the glass ball test method before the 1980s. It uses an automatic particle counter equipped with optical technology to directly measure the size and number of particles passing through, and finally evaluate the filtration ratio of particles of a certain size, and determine that the filtration accuracy is the same. It is the size (micron) under the specified ratio. In the early years, the glass ball method was used in foreign filter material companies by Boss in Italy and Bekaert in Belgium. It was based on the filter accuracy measurement standard, namely the MIL F 8815D 'Glass Bead Passing Method'. At that time, many companies used this standard to evaluate filters. China's aviation standards HB5825 and HB6146 (general technical conditions for aviation filters) clearly stipulated the use of F 9, F 13, F 15, F 17 and F 19 in the maximum particle passing test. The test methods of different size distribution of glass microbead powder are equivalent to MIL F 8815D. After entering the 1990s, the more famous foreign filter material companies no longer use MIL F4 8815D, but adopt the ISO4572 (changed to ISO16889 in 1995) standard, which means that they have passed the test method many times. Figure 1 is the system circuit diagram of the multiple-pass test shown on the sample by Bekaert. Lydall and Bekaert are the first filter material manufacturing companies in the world to learn from the filter filtration accuracy evaluation method. They directly equate the definition and evaluation method of the main performance of the filter with the filter material they have produced, and are welcomed by filter manufacturers. , It has created great convenience for the design and selection of new filters and the test and finalization, and made many detours.

GESTER International Co.,Limited guarantees to providing quality products and services.

GESTER International Co.,Limited intends to make enough profit to generate a fair return for our investors and to finance continued growth and development in textile testing equipment.

The only cardinal rule with adding animation is to keep high-quality on textile testing equipment.

textile testing equipment is attracting a great positive feedback from the customers. And many of our clients are fully satisfied with it.

GESTER International Co.,Limited guarantees to providing quality products and services.

GESTER International Co.,Limited intends to make enough profit to generate a fair return for our investors and to finance continued growth and development in textile testing equipment.

The only cardinal rule with adding animation is to keep high-quality on textile testing equipment.

textile testing equipment is attracting a great positive feedback from the customers. And many of our clients are fully satisfied with it.

Custom message