textile testing

Research on moisture permeability test test of medical protective clothing

by:GESTER Instruments

2022-09-04

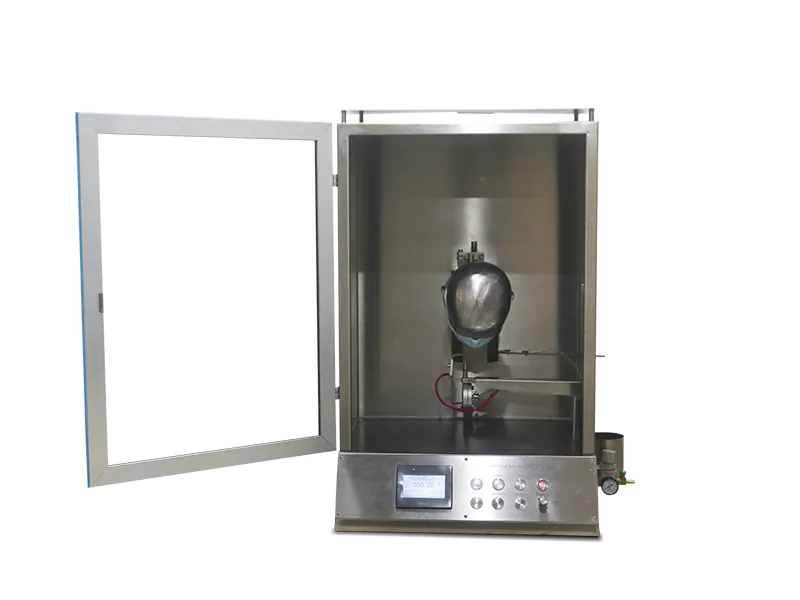

Human body heat is dissipated through radiation, conduction, convection and evaporation. In a static state, the amount of perspiration per adult per day is 700 ~ I 200; when carrying goods outdoors at 32 35 ℃, 200 ~ 200 per day will be excreted. 000 perspiration, which is a feeling of sweating. About 87.5% of the heat of the human body is discharged through the skin. Therefore, the clothing with the largest contact area with the skin plays a vital role in the heat dissipation of the human body. If the moisture permeability of the clothing is 500 g/( m2·24) Above, you can maintain the comfort of wearing I - Medical protective clothing is a special functional clothing. The minimum condition for clothing is to meet the physiological needs of people. If this condition is not met, no matter how good the function is no“SARS”During the period, the medical staff in the isolation area wore multi-layer protective clothing and performed various operations in an environment where the air conditioner was turned off. As a result, some medical staff suffered from chest tightness, shortness of breath, and profuse sweating, resulting in collapse and fainting. The moisture permeability and wearing comfort are poor, so the moisture permeability has become the focus of attention and research. This paper will focus on the analysis of the fabric structure, moisture permeability and related test standards of medical protective clothing. 1 Fabric moisture permeability test 1.1 Test methods The standard test methods for fabric moisture permeability are generally the test of the water vapor transmission rate of the fabric and the test of the evaporative heat transfer impedance. Researchers often use the water vapor resistance to evaluate the human sweat from the body surface through the fabric to the environment. The ability to transfer includes the sweating hot plate method and the sweating dummy method, while fabric and clothing manufacturers tend to use the moisture permeable cup method, that is, under a certain temperature, a certain humidity and a constant wind speed, through the fabric per unit time. The water vapor per unit area, also known as the moisture permeability, is used to evaluate the moisture permeability of the fabric. 1.2 The test standard moisture permeability is an indicator closely related to the wearing comfort of protective equipment]. The moisture permeability test methods often used in medical protective equipment in the world mainly include American standard ASTM E96, Japanese standard JIS 1099, international standard ISO 2528, British standard BS3424 and my country's national standard GB/T 12704 1991. The test conditions, so the test value is sometimes very large. It can be seen from the comparison that although all countries use the standard to test the temperature permeability of the fabric, the applicable objects of the national standards are different. The ASTM standard has the widest application range and can be used for any sheet. Therefore, the experimental conditions, sample size range and test time interval are very wide. The ASTM standard requires that the selected standard test conditions and the use environment of the material are close to the relative humidity specified by the B method in the Chinese standard, which is difficult to control during the test. Moreover, it does not meet the actual use conditions of the fabric. The Japanese standard and the Chinese standard have the same scope of application. They are both textile products, so the test method is very close, but there is no inverted cup method in the test method in my country. 2 Experimental part 2.1 Materials In order to have an understanding of the moisture permeability of protective clothing fabrics, a protective clothing polytetrafluoroethylene (PfFE) laminated fabric was developed, and other types of medical protective clothing fabrics were collected. Different design structures and composite layers need to be adopted, and the sample specifications are shown in the table l’ The fabric is the developed polytetrafluoroethylene (PfFE) multi-functional protective clothing fabric, which is a composite sample of 2 layers. Although it feels slightly harder, it can improve the wear resistance;’The fabric is a polyurethane (PU) coated fabric; the emblem and the fabric are thermoplastic polyurethane (TPU coated non-woven fabrics with different areal densities, and the areal densities are 50-83 g/m2 in turn; 10. The fabrics are disposable protective clothing with high density. The efficiency of non-oily particles of medical protective clothing such as polyethylene non-woven fabrics (NaCl particle glue (075 μm)) is generally above 95 (GB/T 2-2003 stipulates that it is not less than 70. 2.2 Instruments and methods Test equipment: KYKY-28008 scanning electron microscope; LFY-216A moisture meter; JD400-3 electronic balance (accuracy 0.001 Method: moisture permeability comparison experiment and moisture permeability test under multi-layer wear GB/T 12704-91 method - desiccant Method (positive cup) and GB/T 12704-91 method—the test method of evaporation method (positive cup) and refer to American standard ASTM E96 and Japanese standard JIS.”test conditions (temperature (38± ) ℃ relative humidity 50± 2) % moisture vapor transmission formula: WVT = 24 ml A ? t In the formula, WVT is the moisture permeability of the sample per square meter per day (g/( ~ 2·24 h)); public is the weight of the same experimental combination (g); is the experimental time (h); is the experimental area of the real sample (open) each time the test sample is not less than 10%, the relative error is less than 10%. 3 Results and discussion 3.1 Observation of fabric surface structure by scanning electron microscope

GESTER International Co.,Limited offers a ton of features and capabilities to help you acquire and retain customers, boost sales and manage contacts.

go to GESTER Instruments to get an amazing offer at favorbale price. the textile testing equipment tensile tester manufacturers actually works and is worth a try.

GESTER International Co.,Limited has a number of producing line for producing textile testing equipment.

Further dialogue of GESTER Instruments between the approaches, the chapter concludes, could lead to actionable advice on more robust policies that drive both structural change and competitiveness upgrading.

The global market is estimated to reach a value of almost tensile tester manufacturers in the next decade. have a robust position in the tensile tester manufacturers market because of its proven high potency in tensile tester manufacturers.

GESTER International Co.,Limited offers a ton of features and capabilities to help you acquire and retain customers, boost sales and manage contacts.

go to GESTER Instruments to get an amazing offer at favorbale price. the textile testing equipment tensile tester manufacturers actually works and is worth a try.

GESTER International Co.,Limited has a number of producing line for producing textile testing equipment.

Further dialogue of GESTER Instruments between the approaches, the chapter concludes, could lead to actionable advice on more robust policies that drive both structural change and competitiveness upgrading.

The global market is estimated to reach a value of almost tensile tester manufacturers in the next decade. have a robust position in the tensile tester manufacturers market because of its proven high potency in tensile tester manufacturers.

Custom message