textile testing

Detecting the pilling and pilling properties of knitted fabrics by the circular trajectory method

by:GESTER Instruments

2022-08-31

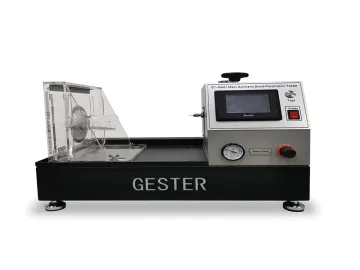

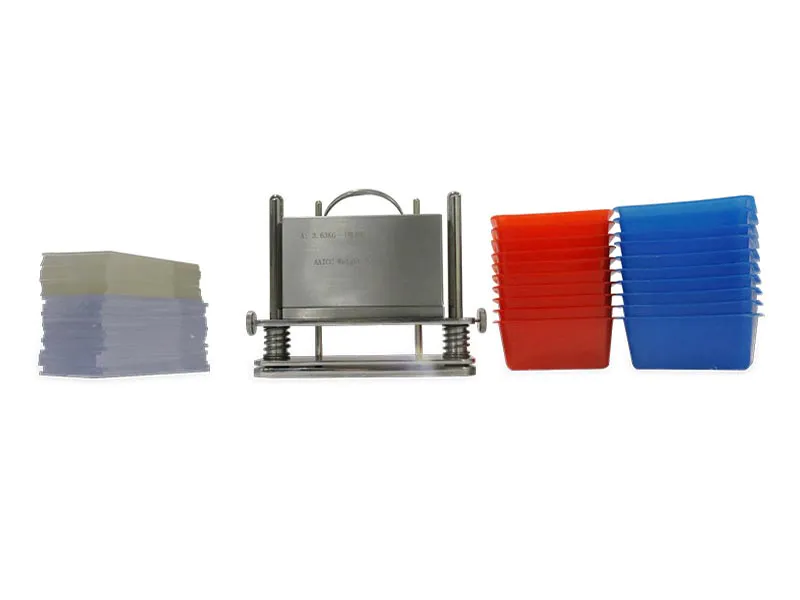

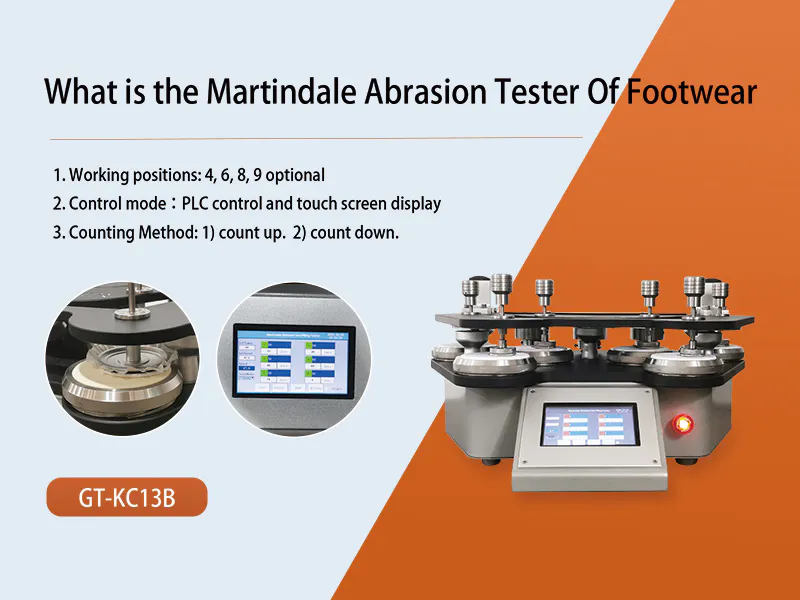

There are many varieties of knitted fabrics. During the actual wearing and washing process of knitted fabrics, due to continuous friction, the fibers on the surface of the fabric are exposed on the surface of the fabric, and the surface of the fabric is fluffy. This phenomenon is called“fluff”. If these hairs cannot fall off in time during continuous wearing, they will be entangled with each other and rubbed into many spherical particles, usually called“pilling”. These hair balls protruding on the surface of the fabric are easily attached to dirt and dust, which seriously affects the wearing performance and appearance of the fabric. Usually, there are four main test methods for fabric pilling: random flipping pilling test method, Martindale abrasion test method, rolling box pilling method and circular trajectory pilling method. (Hong Kong) Co., Ltd. is a manufacturer of textile testing equipment, which can provide testing equipment corresponding to the testing method. Customers in need are welcome to inquire. In addition, the R&D engineer described the pilling and pilling performance of fabrics detected by the circular trajectory method. Test sample: polyester-cotton knitted fabric Test process: 1. Sample making: (1) Pretreatment: If pretreatment is required, the samples can be washed or dry cleaned by the method agreed by both parties. (In order to protect the friction surface of the pilling box and the sample tube from the influence of residual lubricant or finishing agent on the fabric, pretreatment is recommended) (2) Cut 4 samples from the fabric sample, the size is 125mm*125mm, Cut another swatch of the same size as a comparison sample for grading. The 2 samples were folded inward along the longitudinal front, and the 2 samples were folded inward along the transverse front, and sewed with a sewing machine at a distance of 12 mm from the edge. (3) Turn the sutured specimen eversion with the front side facing outwards. Cut 6mm ports at each end of the sample tube to remove sewing distortion. Put the sample on the polyurethane sample carrier tube and fix it with PVC tape (make sure that 6mm of each end of the polyurethane is exposed, and the length of the tape should not exceed 1.5 times the circumference of the polyurethane tube). 2. Test steps: (1) Clean the pilling box; (2) Put the 4 sleeved sample tubes into the box, close the box cover firmly, and set the counter to the required number of rotations; (3) Preset number of turns. Agreement times. If there is no agreement, the coarse fabric is turned over for 7200 revolutions, and the fine imitation fabric is overturned for 14400 revolutions; (4) Start the pilling box, after the test is completed, take out the sample, go out the stitching, and conduct the sample rating. 3. Pilling grade evaluation: Under the standard light source, compare the rating with the standard sample photo, that is, let multiple raters compare and analyze the sample and the standard sample photo in the rating box, and use the result as the fluffing of the sample. ball rating. The sample photo method adopts five grades, 1-5 respectively. The smaller the grade, the more serious the pilling is, and the better the anti-pilling performance is.

GESTER International Co.,Limited thinks that customer satisfaction is one of the most important determinants of brand loyalty. High-quality service can be the difference between a one-time buyer and a lifelong repeat customer.

All you women out there looking for amazing to dazzle the world try GESTER International Co.,Limited latest collections at GESTER Instruments. Try it!

Consumers like these are interested not just in textile testing equipment they will spend their money on, but also in the human and environmental impact of the supply chain that produces those goods.

GESTER International Co.,Limited prepares for every aspect of running a business, and this includes developing a sound understanding and ability to manage the financial aspects of our company, including financial analysis, taxes and budgeting.

GESTER International Co.,Limited thinks that customer satisfaction is one of the most important determinants of brand loyalty. High-quality service can be the difference between a one-time buyer and a lifelong repeat customer.

All you women out there looking for amazing to dazzle the world try GESTER International Co.,Limited latest collections at GESTER Instruments. Try it!

Consumers like these are interested not just in textile testing equipment they will spend their money on, but also in the human and environmental impact of the supply chain that produces those goods.

GESTER International Co.,Limited prepares for every aspect of running a business, and this includes developing a sound understanding and ability to manage the financial aspects of our company, including financial analysis, taxes and budgeting.

Custom message