textile testing

NFPA 2112:2012 Analysis of flame retardant standards in different regions of industrial fireproof clothing

by:GESTER Instruments

2022-08-29

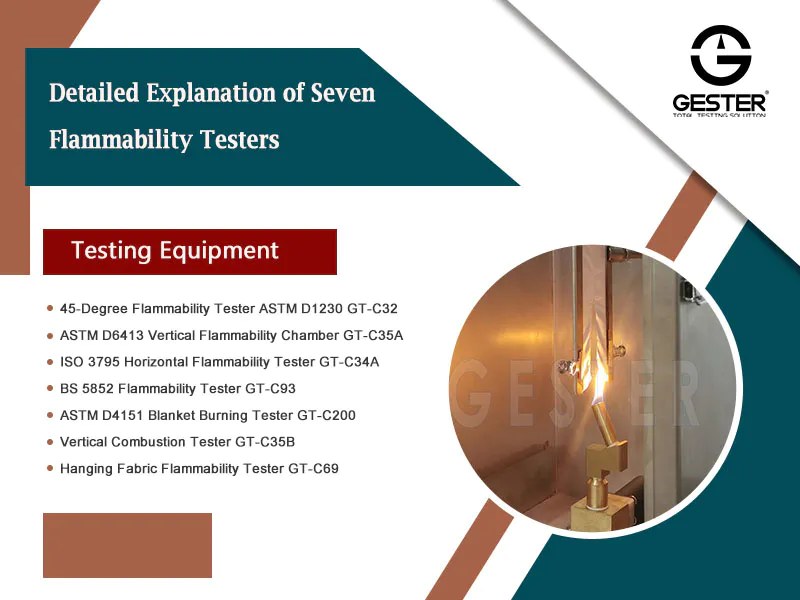

NFPA 2112 fabric is mainly used in mineral development, oil exploration, power protection and other fields. It is a good flame-retardant, anti-static and washable fabric. The fabric is soft and comfortable. NFPA 2112 is a flame-resistant clothing standard for protecting industrial personnel from fire. Nanjing Ruidu Company provides NFPA2112 protective clothing test issued by Spanish AITEX laboratory. NFPA 2112 Standard Name and Purpose: NFPA 2112-2012 Test of Fire Resistant Apparel for Industrial Personnel Fire Protection This standard establishes minimum design requirements, performance, qualification requirements, and fire and fire resistance standards for protective clothing. Section 8.3 Flame Retardant Test: This test method applies to each flame retardant garment fabric layer. NFPA 2112-2012 Standard on Flame-Resistant Garments for Protection of Industrial Personnel against Flash FireNFPA 2112-2012 Standard on Flame-Resistant Garments for Protection of Industrial Personnel against Flash Fire One, with various advanced testing equipment and excellent testing personnel, provides a large number of textile testing and certification services for various textile institutions and clothing brands. AITEX provides technical textile testing according to customer needs, testing according to international, European, American and other standards. We have a variety of advanced equipment and can carry out textile testing of various types and different standards and requirements. We are currently the only textile laboratory in the world that can test all PPE testing items. At the same time, AITEX is also one of the OEKO-TEX100 certification bodies. NFPA 2112 Test Methods and Requirements: NFPA 2112: NFPA Standard for Fire-Retardant Clothing for Industrial Flash Fire The National Fire Protection Association specifies the following for industrial flash fire protective clothing: product marking, user information, clothing design, Fibers, sutures, accessories, signs. NFPA 2112 is a standard for flame retardant protective clothing for industrial use, and it is the test basis for future industrial flame retardant protective clothing laws and regulations. It comprehensively expounds the thermal protection performance requirements of industrial flame retardant protective clothing, including a series of thermal protection performance tests. (1) Vertical combustion performance test. The material is exposed to a standard flame for 12 s, and after the flame is removed, it is determined whether it will be ignited and burned to damage the length, etc. (2) Thermal stability test and NFPA 1975 standard 500°The F oven test is basically the same. (3) Thermal radiation and thermal convection mixed effect protection performance test, referred to as TPP method. This method is tested by placing a 6 square inch piece of cloth under a heat convection and radiant heat source with a total energy density of 2 cal/(cm2?s), and then recording the time required to achieve a second degree burn. The TPP value is the time multiplied by In cal/cal/(cm2?s) values. The higher the TPP value, the stronger the protection provided by the fabric. Different from the vertical burning test, the TPP test can tell us how much energy must be absorbed by the simulated human skin to achieve a second degree burn through various fabrics. The better the protection of the body, the unit TPP value is the most direct reflection of the thermal protection performance. (4) Thermal human body model test. The test is to put a 6-inch-tall mannequin with 122 temperature testers on its body and put it on a fireproof suit and expose it to a 2 cal/cm2?s heat source assembled by a 12-propane flamethrower. The data collected by a temperature tester simulates the degree and location of second and third degree burns that human skin may receive. This is the most advanced life-size thermal burn assessment system in the world today. In order to further simulate the degree of burns of the human body in the actual flame, it is used to test the degree of protection that the clothing can provide under the simulated actual flame conditions. With this test, we can predict the degree of second or third degree burn the body is likely to achieve, the lower the degree of burn all over the body, the greater the chance of survival. NFPA 2112 Test method for flame resistance of textiles(vertical test)- Relevant standard:- ASTM D6413-2008 Fire resistance of textiles-Vertical method- ASTM D6413-2008 Standard test method for flame resistance of textiles(vertical test)- GB 8965-1998 Flame retardant protective clothing - ISO 15025:2000 Protective clothing -- Protection against fire and heat -- Test method for limited flame spread -- ISO 15025:2000 Protective clothing -- Protection against heat and flame -- Method of test for limited flame spread- EN ISO 11611:2007 Protective clothing for use in related processes - EN ISO 11611:2007 Protective clothing for use in welding and allied processes (only for clause 6.7 flame spread (code letter A1 or A2)) (Supersede EN 470-1)- EN ISO 11612:2008 Protective clothing - Heat and fire resistant clothing - EN ISO 11612:2008Protective clothing— Clothing to protect against heat and flame (only for clause 6.2 Limited flame spread (code letter A1 and/or A2)) (Replaces EN 531:1995) - EN ISO 14116-2008 Protective clothing - Protection against fire and heat - Materials for limiting the spread of flame , Material assemblies and clothing - EN ISO 14116-2008 Protective clothing - Protection against heat and flame - Limited flame spread materials, material assemblies and clothing (Replaces EN 533:1997)

When you find yourself in need of textile testing equipment tensile tester manufacturers, you may not know where to begin. And that's OK! Search out GESTER International Co.,Limited to handle your textile testing equipment needs.

We have professional skills and advanced facilities in textile testing equipment and many years of experience in tensile tester manufacturers industry. Choose our products at GESTER Instruments, and you will get supreme buying experience in return.

tensile tester manufacturers problems are nothing new, almost every one of us have to go through them at some point of our lives and some of us never get rid of them. with the development of tensile tester manufacturers technology, now provides a perfect cure for that.

When you find yourself in need of textile testing equipment tensile tester manufacturers, you may not know where to begin. And that's OK! Search out GESTER International Co.,Limited to handle your textile testing equipment needs.

We have professional skills and advanced facilities in textile testing equipment and many years of experience in tensile tester manufacturers industry. Choose our products at GESTER Instruments, and you will get supreme buying experience in return.

tensile tester manufacturers problems are nothing new, almost every one of us have to go through them at some point of our lives and some of us never get rid of them. with the development of tensile tester manufacturers technology, now provides a perfect cure for that.

Custom message