textile testing

The steps of the needle flame experiment

by:GESTER Instruments

2022-07-20

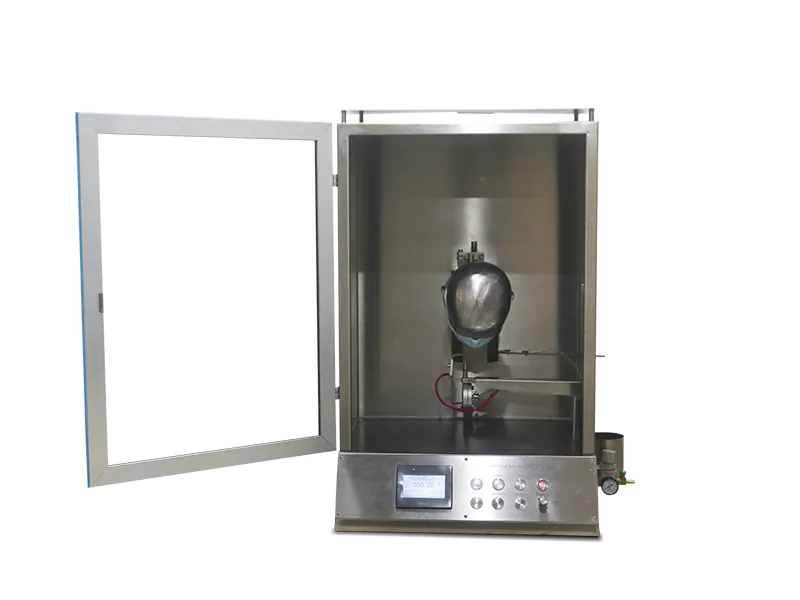

Experimental instrument: Needle flame testing-equipment' target='_blank'>tester Scope of application: Suitable for lighting, low-voltage electrical appliances, household appliances, machine tool electrical appliances, motors, power tools, electronic instruments, electrical instruments, electrical connectors, accessories and other electrical and electronic equipment and their parts and components. Research, production and quality inspection departments, as well as the industries of insulating materials, engineering plastics or other solid combustible materials, conduct simulation tests of small flame ignition sources. Comply with the standards: GB4706.1, GB5169.5-2008, IEC60695-2-2IEC60695-11-5 and other related standards. Experimental principle: The needle flame tester is made of the specified size (Φ0.9mm ) needle burner, with a specific gas (butane), to 45°The test sample is ignited in a fixed direction at an angle, and the ignition hazard of the small flame caused by the fault condition inside the equipment is evaluated according to whether the test sample ignites, the holding time and the burning length. Experiment preparation of needle flame tester: 1. The instrument is placed in a room with ventilation equipment (or a small laboratory with a special ventilation hood), so that the exhaust gas can be discharged in time after the test. 2. Hang the two matching weights with copper wires (connected to the sample holder) under the support plate through the two pulleys on the left end of the support plate (through the corresponding holes). As shown in the figure: 3. Prepare and clamp the sample according to the standard requirements. 4. Adjustment of the proximity switch A. Loosen the nut fixing the proximity switch so that it can move left and right; B. Press down“left row"Press the button, the trolley moves forward automatically, when the sample touches the glow wire head, move the proximity switch by hand to stop the trolley and fix the proximity switch; C. Press“heating"button to adjust the current adjustment knob. According to the requirements of the sample, adjust the appropriate current value, and check whether the thermometer reaches the temperature required by the test requirements. When the sample touches the glow wire head, the limit electromagnet is released, and the sample can only move forward 7mm under the pulling force of 1N weight. (The distance can be adjusted) When the glow wire tester test is completed, the“heating"The button pops out, then turn the current adjustment knob to the minimum.

GESTER International Co.,Limited is committed to fulfill the demands of our customers with using textile testing equipment.

The Global textile testing equipment Leader. GESTER International Co.,Limited will build a unique portfolio of GESTER Instruments and related brands, striving to surpass our competitors in quality, innovation and value, and elevating our image to become the textile testing equipment company most customer turn to worldwide.

To derive the optimal value out of tensile tester manufacturers textile testing equipment for your home, make sure they're purchased from a globally certified organization to ensure quality in use. Such an offer can be found at GESTER Instruments.

GESTER International Co.,Limited is committed to fulfill the demands of our customers with using textile testing equipment.

The Global textile testing equipment Leader. GESTER International Co.,Limited will build a unique portfolio of GESTER Instruments and related brands, striving to surpass our competitors in quality, innovation and value, and elevating our image to become the textile testing equipment company most customer turn to worldwide.

To derive the optimal value out of tensile tester manufacturers textile testing equipment for your home, make sure they're purchased from a globally certified organization to ensure quality in use. Such an offer can be found at GESTER Instruments.

Custom message