textile testing

Brief introduction to the determination of the pilling performance of GB fabrics

by:GESTER Instruments

2021-06-30

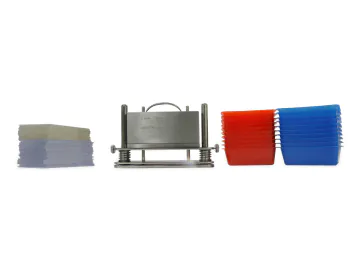

1. Reference standard: GB/T 4802.4 Determination of fabric fuzzing and pilling performance. Part 4: Random tumbling method (GB/T 4802 The determination of fabric fuzzing and pilling performance consists of four parts, namely the circular path method and the modified Martin Four methods to test the pilling performance of fabrics: pilling method, pilling box method and random tumbling method.) 2. Test instrument: random pilling tester 3. Test principle: put the sample in the test box, Under the action of the rotation of the impeller, the cork lining of the storage box rubs continuously at random. After the set time is reached, samples are taken out for grading. 4. Main instruments and appliances: 1. Pilling box 2. Cork cylinder liner: length 452mm, width 146mm, thickness 1.5mm. The cork pad needs to be replaced after 1 hour of use. 3. Air compression device: make the test chamber reach a certain pressure (14-21KPa). 4. Adhesive, gray short cotton. 5. Rating box: Use white fluorescent tubes or light bulbs to illuminate. The position of the light source is maintained at 5°-15° with the plane of the sample, and the observation direction is maintained at 90°±10° with the plane of the sample. The distance between the eyes with normal corrected vision and the specimen should be 30cm-50cm. V. Preparation of samples: (1) Pretreatment: If pretreatment is required, the samples can be washed or dry-cleaned by the method agreed by both parties. (2) Take 3 samples from the fabric sample, the size is (105±2)mm*(105±2)mm, and cut a piece of cloth sample of the same size as the comparison sample required for grading. Mark the sample, seal the edge of the sample with an adhesive, and hang to dry. 6. Test procedure: 1. Put three samples from the same sample into different test chambers for testing. 2. Put the gray short cotton and the sample into the test chamber (weight 25mg, length 6mm) 3. Set the test time to 30min, start the instrument, and open the air flow valve. 4. After the test is over, take samples and grade them, and use a vacuum cleaner to clear the remaining cotton wool. 7. Rating of test results: The rating box should be placed in a dark room. Place the tested sample and an untested sample in the middle of the sample plate of the grading box along the longitudinal direction of the fabric (if the test sample is pre-treated before the test, the control sample should also be pre-treated. Correspondingly, if the test sample has not been tested before Pretreatment, the control sample should be the sample without pretreatment). The tested sample is placed on the left, and the untested sample is placed on the right. The rating is subjective, and it is recommended that at least 2 people rate it. The appearance of the sample and the corresponding grade are as follows: Record the grade of each sample, and the result of a single person's rating is the average value of the grades of all samples. The test result of the sample is the average of the ratings of all personnel. If the average value is not an integer, it shall be corrected to the nearest 0.5 level and indicated by '-If the difference between a single test result and the average is more than half a level, the level of each sample should be reported at the same time. More about the random pilling tester: http://www.standard-groups.com/OfficeFurniture/

As a entrepreneur, being trapped in a company under multiple quality problems never appealed to GESTER International Co.,Limited.

A detailed plan must be developed if we hope to reach your profitability goal. Once we have a certain figure in mind, GESTER International Co.,Limited and our staff need to determine all the steps necessary to reach that goal and act on them.

GESTER International Co.,Limited have been an established and popular company with an excellent track record for the best customer satisfaction.

[拓展名称] include a great variety of devices with a wide range of complexity: from simple tensile tester manufacturers used since prehistoric times to the complex of modern mechanized tensile tester manufacturers.

As a entrepreneur, being trapped in a company under multiple quality problems never appealed to GESTER International Co.,Limited.

A detailed plan must be developed if we hope to reach your profitability goal. Once we have a certain figure in mind, GESTER International Co.,Limited and our staff need to determine all the steps necessary to reach that goal and act on them.

GESTER International Co.,Limited have been an established and popular company with an excellent track record for the best customer satisfaction.

[拓展名称] include a great variety of devices with a wide range of complexity: from simple tensile tester manufacturers used since prehistoric times to the complex of modern mechanized tensile tester manufacturers.

Custom message