textile testing

How does the textile industry rise under pressure?

by:GESTER Instruments

2022-08-04

China's largest cotton textile producer—— Weiqiao Textile Co., Ltd. announced on May 21 that in order to strengthen industrial upgrading, increase the proportion of mid-to-high-end products, and achieve the principle of high-quality development, the company is building an automated and intelligent spinning and weaving production line to achieve Eliminate, retain, and develop, realize while compressing, improving, and transforming, and embark on a path of transformation and upgrading of traditional manufacturing. The new smart factory will realize the integration of spinning and weaving and the intelligent control of the whole process. The plant plans to invest about RMB 820 million. It is expected that the equipment will be installed by the end of July 2019 and put into operation in October 2019. After the completion of the construction of the plant, it can produce 15,000 tons of high-end compact spinning yarn and 35 million yards of high-end fabrics per year. The project will use“Internet+”, product automatic inspection, robot application, automatic transportation tool application, use of energy-saving equipment and other measures. The intelligent rail conveying system of the production line has a length of 35 kilometers. From roving to product warehousing, it is fully automated for transportation and automatic packaging. The entire process does not involve any direct labor. With the help of the intelligent control system platform, the production line can be remotely managed through terminal devices such as mobile phones, tablets, and computers, and each process and operation point can be monitored visually in real time. In addition, the production line also has multiple functions such as order progress warning, equipment status warning, quality over-standard warning, environmental over-standard warning, energy consumption over-standard warning, one-click generation of production quality reports, real-time monitoring of quality data, real-time order tracking, and seamless integration of ERP. , all devices will realize data integration analysis. With the completion and commissioning of the company's new intelligent production line, it will bring about a substantial increase in production efficiency. For example, the blowing and carding system reduces the number of barrel changes by 10%; the sliver and spool combing automation system realizes automatic roll change, automatic piecing, and automatic lap; the thickness and fine network intelligent automatic track system can realize doffing and stopping within 3 minutes, doffing The yarn success rate, the empty tube replacement success rate, and the spinning-in success rate are close to 100%; the spun yarn adopts a 1,824-spindle super-long spinning frame; the AGV can conveying system realizes the automatic conveying of cans and is accurate; The quality monitoring system can significantly improve the weight unevenness and evenness level; the weft insertion rate of the loom reaches 2,565 times/min. These data representing the industry-leading level reflect the new kinetic energy generated by Weiqiao Textile's technology. After the completion of this intelligent spinning and weaving integrated workshop, the number of workers in this production line will be reduced by 90% compared with the current number of workers in the company's current production line of the same scale, which not only reduces the labor intensity of workers, reduces labor costs, but also improves product quality. The competitiveness of the company will be greatly enhanced, high-quality development will be achieved, and the overall industrial upgrading will be promoted. In the development practice of the enterprise for more than 20 years, Weiqiao Textile insists on taking innovation as the first driving force to lead the development of the enterprise, and puts innovation in the core position of the overall development of the enterprise. Through the continuous innovation of intensive management and management mechanism, it has formed a Set of unique style of enterprise management innovation management mode. The consumption indicators of Weiqiao Textile are at a relatively low level in the industry, which enables the enterprise to maintain the development advantages of low cost and high quality. In the next step, the company will continue to actively practice, strengthen cooperation with scientific research institutes, increase technology research and development, continuously strengthen industrial upgrading, and improve the level of intelligent branch construction. Through process reengineering, work method innovation, management model innovation, etc., Jointly promote the development of the textile industry in the direction of green and low-carbon, digitalization and intelligence, and make new contributions to building a strong textile country. Xianyang Xinxing Textile Industrial Park is moving towards“Smart Manufacturing”Xianyang, the ancient capital of accelerating industrial agglomeration, is not only a famous historical city in China, but also a famous textile city. It is the largest cotton textile base in Northwest China. Today, in the new historical development period, Xianyang Xinxing Textile Industrial Park is undergoing transformation and development, moving towards the direction of intelligent manufacturing and multi-industry aggregation. In Xianyang Xinxing Textile Industrial Park, the first intelligent factory in northwest China built by Dukepu Garment Company has entered the stage of equipment debugging. People only need to stand at the designated position, the device will automatically read the height and weight, and then by taking frontal and side photos, the device can collect various body data of the person. Subsequently, the data center builds a three-dimensional model to match the corresponding sample, and the workers make it according to specific requirements. Yang Junle, Chairman of Shaanxi Xianyang Dukepu Garment Co., Ltd.:“For remote and online customer groups, we use remote imaging data collection, and for those who come to the experience store, we use the intelligent system for collection and experience.”In addition to technological innovation, there is also product innovation. In 2018, the company also invested more than 1 million yuan to establish a research and development center in cooperation with Hong Kong Polytechnic University and Xi'an University of Technology, and produced a smart temperature-controlled clothing that has just obtained a national patent. Sun Yu, Director of the R&D Center of Dukepu Garment Co., Ltd.:“We have developed a smart temperature-controlled cotton-padded jacket, which can adjust the temperature through the mobile phone APP. It has three gears, high, medium and low, which is convenient and fast, so that the clothes can heat up quickly, and its battery life can reach more than 8 hours outdoors.”Today, Xianyang Xinxing Textile Industrial Park has been formed“Equipment manufacturing, high-tech, textile and apparel”three industrial systems. The development of the above textile enterprises and the upgrading of industrial clusters are inseparable from the presence of scientific research. Only continuous technological innovation, R&D and creation can enhance their own strength and become a leader in the industry.“wind vane”!

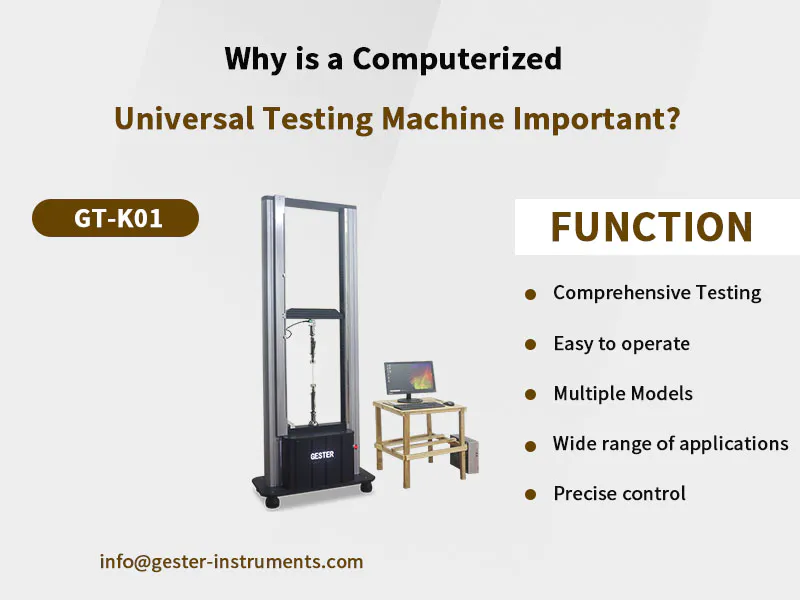

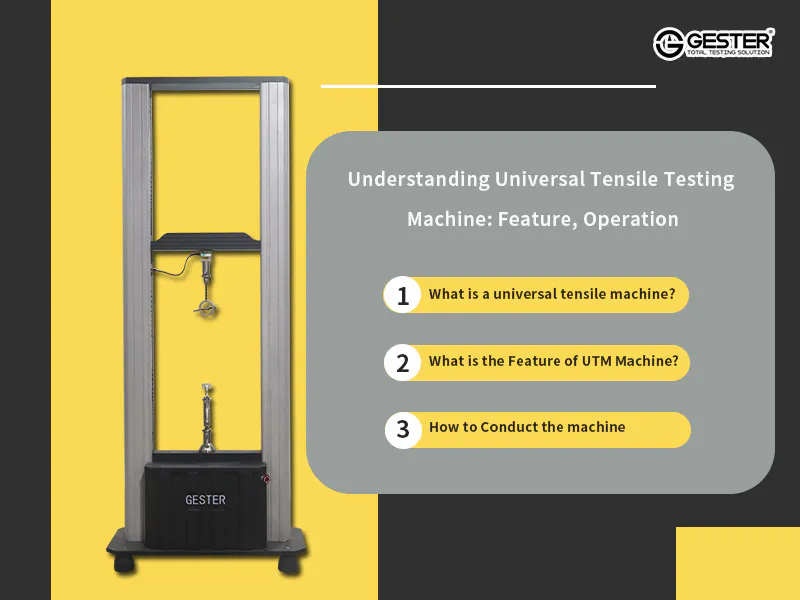

Most places have a few choices when it comes to tensile tester manufacturers textile testing equipment distributors, but it can sometimes be difficult to find the right supplier for your needs. The quality of textile testing equipment is critical to tensile tester manufacturers.

No more need to worry about the condition of your tensile tester manufacturers with , a textile testing equipment that helps in making your tensile tester manufacturers look tensile tester manufacturers like never before. Visit GESTER Instruments to know more.

To properly understand what customers want, when, why and how they want it, GESTER International Co.,Limited needs to pivot toward sentiment analysis, a burgeoning technology that taps into consumer demand based on natural language processing.

textile testing equipment is attracting a great positive feedback from the customers. And many of our clients are fully satisfied with it.

Most places have a few choices when it comes to tensile tester manufacturers textile testing equipment distributors, but it can sometimes be difficult to find the right supplier for your needs. The quality of textile testing equipment is critical to tensile tester manufacturers.

No more need to worry about the condition of your tensile tester manufacturers with , a textile testing equipment that helps in making your tensile tester manufacturers look tensile tester manufacturers like never before. Visit GESTER Instruments to know more.

To properly understand what customers want, when, why and how they want it, GESTER International Co.,Limited needs to pivot toward sentiment analysis, a burgeoning technology that taps into consumer demand based on natural language processing.

textile testing equipment is attracting a great positive feedback from the customers. And many of our clients are fully satisfied with it.

Custom message