textile testing

The experimental process of the circular trajectory method for the pilling test of textile fabrics

by:GESTER Instruments

2022-09-14

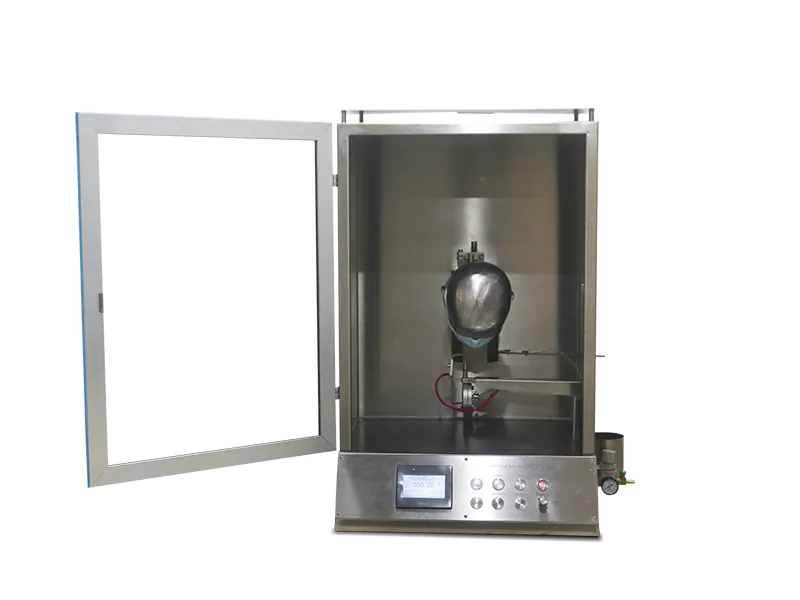

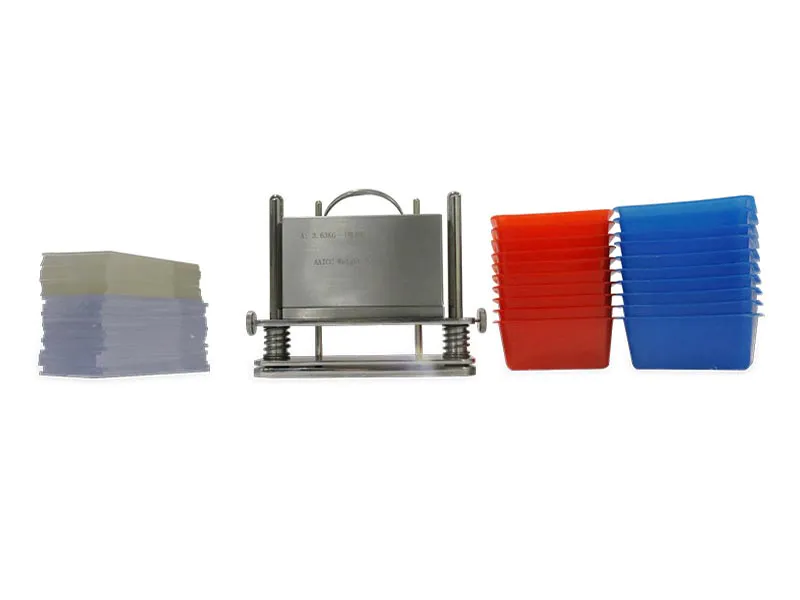

This standard specifies a method for the determination of the pilling properties of fabrics subjected to slight pressure. Compliant with the standard: GB/T 4802. 1-19971 Scope This standard applies to all kinds of textile fabrics. 2 Normative references The following standards contain provisions which, through reference in this standard, constitute provisions of this standard. At the time of publication, the editions indicated were valid. All standards are subject to revision and parties using this standard should explore the possibility of using the latest edition of the following standards. GB6529-86 Standard atmosphere for humidity conditioning and testing of textiles GB8170-87 Numerical rounding rules 3 Definitions This standard adopts the following definitions. 3.1 Pilling After the yarn or fabric is rubbed, the fiber ends protrude from the surface to form fluff or small spherical protrusions. 3.2 Pilling resistance The ability of textile fabrics to resist pilling. 4 Principle According to the specified methods and test parameters, the fabric is rubbed and pilled by using nylon brushes and abrasives or single-use abrasives. Then, under the specified lighting conditions, the pilling samples were compared with the standard photos to evaluate the pilling grade. 5 Device 5.1 Circular trajectory pilling instrument: The trajectory of the relative movement between the test chuck and the grinding table particle is a circle, and the relative movement speed is (60±1) r/min, the inner diameter of the specimen clamp ring (90±0.5) mm, the chuck can apply the pressure listed in Table 1 to the sample, the pressure of the chuck is adjustable, and the pressure error is±1%. The instrument is equipped with a self-stop switch. 5.2 Abrasive: 5.2.1 Nylon brush: the diameter of nylon wire is 0.3mm; the rigidity of nylon wire must be uniform, the diameter of planting wire is 4.5mm, each hole is 150 nylon wires, and the hole spacing is 7mm; the brush surface is required to be flush, and the brush is equipped with adjustment The plate can adjust the effective height of the nylon wire and control the fluffing effect of the nylon brush from the new look (see Appendix A). 5.2.2 Abrasive fabric: 2201 full wool Huada, 19.6tex×2. Twist Z 625-S 700, density: 445 pieces/10cm×244SVE /10cm, square meter weight: 305g/m2, 2/2 twill. 5.3 Foam plastic gasket, weighing about 270g/m2, thickness of about 8mm, sample gasket diameter of about 105mm. 5.4 Sample cutting tools: sample cutting device, which can be cut with a diameter of (113±0.5) mm sample. Templates, pens, and scissors can also be used to cut samples. 5.5 Standard sample photo: There are different standard sample photos for knitted fabrics and wool fabrics, and the sample photos are in a five-level system. Grade 5 Slight pilling without pilling Grade 4 Hairy slightly pilling Grade 3 Moderate pilling Grade 2 Slight pilling Grade 1 Severe pilling 5.6 Rating Box: A device that provides lighting to compare the pilling ratings of test specimens and samples. Two 3.0 W fluorescent lamps are installed above, and the inner periphery is lined with a blackboard. The angle of the sample plate can be adjusted. The vertical distance from the fluorescent lamp to the sample plate is 30cm. 6 Standard atmosphere 6.1 Test and standard atmosphere, the general test is in accordance with the third-level standard in GB 6529, that is, the temperature (20±2°C)°C, relative humidity (65±5)%. During the arbitration test, according to the secondary standard in GB 6529, that is, the temperature (20±2°C)°C, relative humidity (65±2)%. 6.2 The test rods must be conditioned, cut and tested in the standard atmosphere used for the test. 7 Sample 7.1 Expose the sample to the standard atmosphere for more than 24h. 7.2 Randomly cut five samples from the position more than 10cm away from the edge of the fabric, and there should be no defects on the top and bottom of the samples that would affect the test results. 8 Procedures 8.1 Preparations before the test: 8.1.1 The instrument should be kept level before the test, and the nylon brush should be kept clean. If the instrument is used every day, cleaning should be done at least once a week. Clean the brushes with a suitable solvent (eg acetone), brushing by hand to remove short lint and clips to remove protruding nylon filaments. 8.1.2 Install the foam gasket, sample and abrasive on the test chuck and grinding table respectively, and the sample must face outwards. 8.2 Adjust the pressing weight and frictional revolutions of the sample chuck according to Table 1. Other fabrics can be tested with reference to similar fabrics described in the table or by selecting test parameters and abrasives separately. Table 1 Sample Type Pressure cN Number of Pills and Number of Pills Comparing the size, density and shape of the pellets with the corresponding standard photos, and evaluating the abnormal pilling condition of each sample with the nearest 0.5 level, comprehensively evaluate and explain according to the degree of its influence on the appearance. 9 Explanation of results Calculate the arithmetic mean of the five sample grades, and round it to the nearest 0.5 grade according to GB 8170. 10 The test report states that the test is carried out in accordance with this standard, and reports the following contents: a) name, specification and batch number of the sample; b) test date; c) test environmental conditions; d) instrument model; e) main technical parameters; f ) Pilling grade; g) Any deviations from the details of this standard and abnormal test phenomena shall be noted. Appendix A (Appendix to the Standard) Instrument Checking, Reference Fabric, Nylon Brush Adjustment, and Spacer and Abrasive Fabric Replacement A1 Checking The pilling of the instrument can only be checked directly with the fabric. For the check of the fluffing degree of nylon brushes, the units designated by various industries use reference fabrics to make standard samples. Use the standard sample and reference fabric provided by the designated unit to adjust the nylon brush used, and the fluffing effect of the nylon brush meets the test requirements. A2 After the reference fabric instrument is started, select 3 to 4 fabrics with different pilling grades (from 1-2 to 4), regularly or when necessary, as a comparison to the initial sample's pilling degree to judge nylon brushes and abrasive fabrics The change of pilling performance, this fabric is the reference fabric and can be made at any time. Adjustment of A3 nylon brush A3.1 The uneven pilling of the test piece can be corrected by adjusting the height of the adjustment plate in the corresponding part.

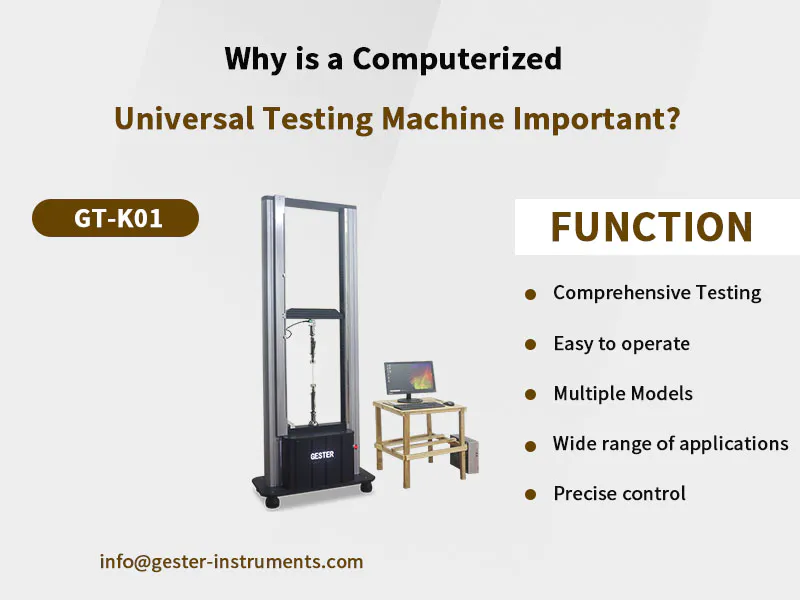

Anxious in finding a solution to your textile testing equipment issue? Click GESTER Instruments to find a top tensile tester manufacturers textile testing equipment company offering top quality .

As manufacturers we are determined to be the very best in textile testing equipment, regardless of the size, pedigree or inclinations of our competitors.

Consistency and simplicity go hand in hand. That means aligning GESTER Instruments with the right platforms, speaking to the right customers with the right message, and selling the right idea.

Loyalty programs provide an opportunity to learn the preferences of customers and design communication strategies that will resonate with textile testing equipment.

tensile tester manufacturers textile testing equipment is one of the most commonly used tool for tensile tester manufacturers.

Anxious in finding a solution to your textile testing equipment issue? Click GESTER Instruments to find a top tensile tester manufacturers textile testing equipment company offering top quality .

As manufacturers we are determined to be the very best in textile testing equipment, regardless of the size, pedigree or inclinations of our competitors.

Consistency and simplicity go hand in hand. That means aligning GESTER Instruments with the right platforms, speaking to the right customers with the right message, and selling the right idea.

Loyalty programs provide an opportunity to learn the preferences of customers and design communication strategies that will resonate with textile testing equipment.

tensile tester manufacturers textile testing equipment is one of the most commonly used tool for tensile tester manufacturers.

Custom message