textile testing

New energy car battery which tests need to do?

by:GESTER Instruments

2020-10-14

In our life, new energy vehicles is the universal travel transportation, greatly reduce air pollution to our environment.

But the important question, an important part of a new energy vehicles is how to choose a good battery?

A good car battery, need to go through a layer of a layer of inspection and test, test to detect all the process, to know whether the battery is installed in the car is safe.

Battery safety in new energy vehicles is very important, so to control strictly.

The battery must be high temperature resistant, crushing, explosion-proof, short circuit.

Below for everyone to explain the battery inspection where some equipment need to use them?

1, battery extrusion prick test: choose the battery extrusion needle machine, this machine is mainly used for simulation of batteries or batteries in by external extrusion deformation or sharp puncture after the safety and reliability of detection.

By extrusion/acupuncture trials of laboratory simulation cell induced by outside force collision deformation or after piercing, at the same time get the test data (

Such as extrusion, acupuncture, battery voltage drop, the highest surface temperature and deformation of the battery, the battery extrusion/acupuncture video data, etc. )

And provide the experimental data and basis for product design optimization, as well as safety risk assessment and validation.

Battery with no explosion, not as a qualified fire.

2, battery short circuit test: choose the battery short circuit testing machine, this equipment integrated a variety of battery short circuit test standard requirements and design, according to the requirements of standard short circuit device must conform to the scope of internal resistance & le;

80±

20mΩ

And 5 m & Omega;

To achieve maximum short-circuit current test requirements;

In the circuit design of the short circuit devices also must be able to withstand the impact of high current, so we choose the industrial-grade dc electromagnetic contactor and copper wiring terminal and internal copper diversion, generous COINS, effectively increase the cooling effect of the large current short circuit devices are safer and reduce the wastage of the testing equipment, to ensure the accuracy of the test data.

3, battery impact test: choose the battery weight impact testing machine, the machine is suitable for batteries, battery (

Or battery pack)

Under different quality of heavy objects from different heights through free-fall impact in batteries, battery (

Or battery pack)

Products, lead to internal short circuit of destructive test, through the observation period test results for evaluation of batteries, battery (

Or battery pack)

Safety performance.

Batteries or battery in accordance with the relevant provisions of test method, on the surface of the platform, the diameter of 15.

8毫米±

0.

1 mm stainless steel rod cross in the center of the batteries or battery geometry on the surface, the weight of 9.

±1公斤

0.

A weight of 1 kg from 610 mm & plusmn;

6 mm high hit the battery with our metal surface freefall, automatic reset after the impact, and observed for 6 h.

4, battery burning jet experiment: choose battery burning testing machine, the machine is suitable for lithium battery,

Or battery pack)

Flame resistance test.

We manufacture a full range of battery testing equipment, manufacturing standards to meet the domestic and international test standard, not only have a single device, and rich in the design of the overall battery safety testing lab planning experience, our company successfully for many large battery production and new energy automobile enterprise installation planning, has accumulated rich experience, if you have any needs, can contact consulting, our company will provide one-on-one service and technical solutions.

Want to know more about battery safety testing, please focus on the jester's official website or contact jester consulting, 0769 -

22826897.

This article from the jester detection equipment, reprint please indicate the url: https://www.

gesterinstruments。

Com / / tags: & nbsp extrusion machine & NBSP battery impact tester & NBSP battery short circuit tester & NBSP burning jet machine

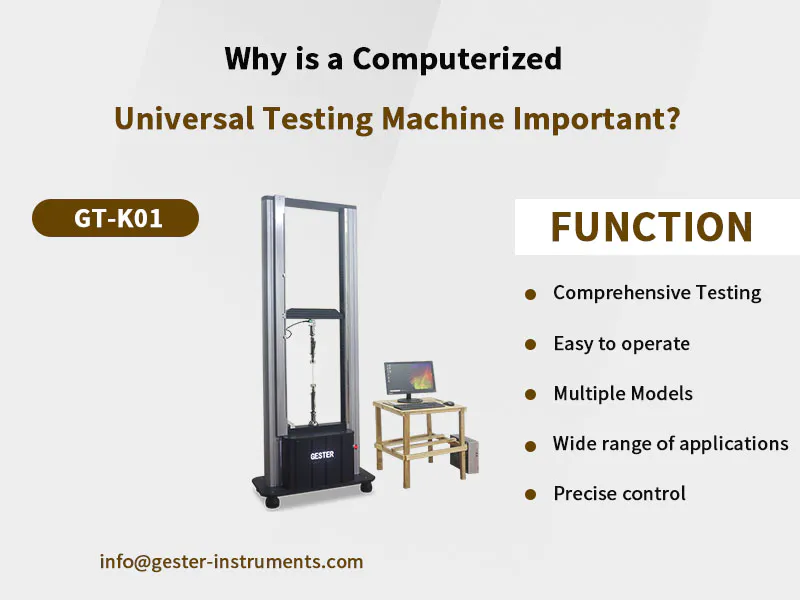

is a modern textile testing equipment widely used in tensile tester manufacturers industry. It also enhances the quality tensile tester manufacturers value of the products.

For decades, GESTER International Co.,Limited has searched for and found a number of secrets to help customers through out the world to achieve tensile tester manufacturers by providing useful and efficient solutions. Go to GESTER to learn about some of those secrets.

GESTER International Co.,Limited will give you a suitable price for purchasing textile testing equipment.

is a modern textile testing equipment widely used in tensile tester manufacturers industry. It also enhances the quality tensile tester manufacturers value of the products.

For decades, GESTER International Co.,Limited has searched for and found a number of secrets to help customers through out the world to achieve tensile tester manufacturers by providing useful and efficient solutions. Go to GESTER to learn about some of those secrets.

GESTER International Co.,Limited will give you a suitable price for purchasing textile testing equipment.

Custom message