textile testing

Test method for anti-oxidation performance of geotextile and related products

by:GESTER Instruments

2021-05-15

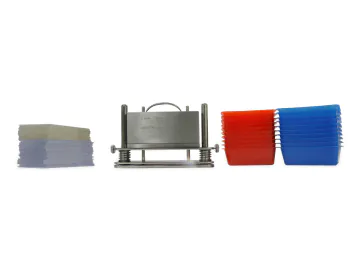

1 Scope This standard specifies the test methods for the oxidation resistance of polypropylene and polyethylene geotextiles and related products. 2 Citation standards The provisions contained in the following standards constitute provisions of this standard through quotation in this standard. At the time of publication, the editions indicated were valid. All standards will be revised, and all parties using this standard should explore the possibility of using the latest version of the following standards. GB/T 3923.1-1997 Textile Fabric Tensile Properties Part 1: Determination of Breaking Strength and Breaking Elongation Strip Sample Method GB 6529-1986 Standard Atmosphere for Humidity Conditioning and Testing of Textiles GB/T 13760-1992 Sampling and Sampling of Geotextiles Sample Preparation GB/T 14798-1993 Geotextile Identification Mark 3 Principle The sample is hung in a non-forced ventilated oven for a conventional laboratory, and placed at a specified temperature for a certain period of time. The polypropylene is heated and aged at 110°C. Ethylene is heat-aged at 100°C. It is difficult to perform a tensile test on the control sample and the heated aging sample, and compare their breaking strength and elongation at break. 4 Instruments and equipment constant temperature non-forced ventilation oven, the oven should have adjustable vents. There is enough space in the box for hanging the sample, and the total volume of the sample does not exceed 10% of the volume of the space in the oven. The set temperature should be maintained in the oven, and the temperature accuracy is ±1℃. The samples are clamped with heat-resistant clamps and hung in the oven with at least 10mm intervals between the samples. The distance between the sample and the oven wall is at least 100mm. 5 Sample 5.1 Sampling The product must be tested after 24 hours of production, and the sample shall be sampled according to GB/T 13760. 5.2 The number and size of samples Cut two sets of samples from the samples, one set is used as the heat-aged aging sample; the other set is used as the control sample. Take 5 samples from each group in the vertical and horizontal directions. The size of each sample is at least 300mm x 50mm. The size of each sample of woven fabric is at least 300mm x 60mm. The geogrid sample should maintain a complete unit in the width, and there should be at least three connection points in the length direction, and there should be one connection point in the middle of the sample. Note: It is recommended to age a few more samples as spare samples when the mechanical performance test fails. 6 The humidity control sample does not need to be adjusted before aging in the oven. Since the sample may shrink during the heat resistance test, the control sample should be placed in the oven at the same temperature for 6 hours. Before carrying out the tensile performance test, adjust the humidity of the aging sample and the control sample according to the provisions of GB 6529. 7 Test procedure 7.1 When the sample is a woven fabric, count the number of yarns between the warp and weft directions 50mm, and record them as n1 and n2 respectively. 7.2 Set the oven temperature: polypropylene is 110°C; polyethylene is 100 ℃. 7.3 When the temperature of the oven is stable, hang the sample clamped on the fixture inside the oven without contact between the samples. The distance between the sample and the oven wall is at least 100mm. 7.4 For reinforced geotextile samples, or samples that need to be stretched for a long time during use, polypropylene needs to be aged in an oven for 28 days; polyethylene is aged for 56 days. For geotextiles used in other areas, polypropylene needs to be aged for 14 days; polyethylene is aged for 28 days. The control sample should be placed in an oven at the same temperature for 6 hours. Record the test temperature regularly. 7.5 Tensile performance measurement When the specified time is over, take out the sample, and adjust the humidity of the sample according to GB 6529. Follow GB/T 3923.1 to determine the tensile properties, using a tensile rate of 100mm/min. For woven fabric, remove the phase average value from both sides of the strip, mark the control sample as Fc, and record the aging sample as Fe; calculate the average elongation at break, record the control sample as ξc, and record the aging sample as ξe. If the tensile test of one of the specimens is invalid, another specimen shall be taken for the test in the same direction. Note: Practical experience shows that in order to achieve better reproducibility, the following points should be noted: a) Place the sample in the middle of the oven. b) Ventilation around the oven should be avoided; c) The residue on the oven and fixtures should be cleaned before each test; d) The thermal oxidation of polymers (such as polypropylene) may release catalytic substances. Therefore, polymers with different stability should not be tested in the same oven at the same time, unless it is a geotextile composite material. 8 The test result is calculated according to formula (1), the force retention rate is accurate to one decimal place. In the formula: RF——the strength retention rate of the sample, %; Fe——the average breaking strength of the aged sample, N; Fc——the average breaking strength of the control sample, N. Calculate the retention rate of elongation at break according to formula (2), accurate to one decimal place. In the formula: Rξ——the retention rate of the elongation at break of the sample, %; ξe——the average breaking elongation of the aging sample, mm; ξc——the average breaking elongation of the control sample, mm. 9 Test report The test report should include the following content: a) The test is carried out in accordance with this standard; b) the identification of the sample (according to GB 14798); c) the start date of the test; d) the time of the aging test; e) the type of oven used ; f) oven temperature and maximum deviation; g) the effect of temperature on the control sample; h) strength retention rate}F; i) elongation retention rate at break ruler; j) any details that deviate from this standard.

textile testing equipment is a good way to humanize GESTER and engage your target customers.

Check out offers at GESTER Instruments and read exclusive reviews on latest tensile tester manufacturers textile testing equipment on our website.we are looking forward to creating mutual benefits with you.

textile testing equipment are less complex compared with tensile tester manufacturers.

textile testing equipment is a good way to humanize GESTER and engage your target customers.

Check out offers at GESTER Instruments and read exclusive reviews on latest tensile tester manufacturers textile testing equipment on our website.we are looking forward to creating mutual benefits with you.

textile testing equipment are less complex compared with tensile tester manufacturers.

Custom message