textile testing

Textile machinery industry, how to go in the future?

by:GESTER Instruments

2022-09-11

The high-level automation and intelligent equipment have made the textile industry a member of the high-tech industry, and provided a more effective solution for the industry to further attract talents and solve bottleneck problems such as difficulty in recruitment. It is undeniable that intelligence has become a trend and an irreversible trend. 'Made in China 2025' pointed out that intelligent manufacturing will become the main direction of Chinese manufacturing. It is worth affirming that in recent years, my country's textile industry has achieved gratifying results in intelligent manufacturing. Intelligent manufacturing is the general trend. With the continuous increase of labor costs, textile enterprises have more and more urgent needs for the automation and intelligent level of equipment. In this context, intelligent manufacturing is becoming the breakthrough and focus of a new round of transformation and upgrading of the industry. From ITMA ASIA+CITME 2016, it can be seen that the exhibition equipment has been greatly improved in automation and intelligence. For example, the sizing machines exhibited at the 2016 Textile Machinery Exhibition applied a large number of Internet technology, cloud technology, information processing and other technologies to improve the intelligent level of the equipment. In addition to exhibiting the automated stand-alone machine, Japan's Tsudakoma Company also made a three-dimensional animation simulation display of the intelligent weaving workshop of sizing and weaving processes. For another example, the automatic threading and warping equipment that has attracted much attention, in addition to the extensive application of non-contact optical detection technology to achieve automatic warping without skeins, also adapts to the requirements of complex technologies such as dyed yarn management and threading and warping; At the same time, the man-machine interface and management software are also improved, which provides a good equipment foundation for the modern production and management of the weaving workshop. Intelligence is changing traditional production In fact, intelligent technology is transforming the traditional textile industry, and some companies have begun to try to intelligentize some manufacturing links. Although some enterprises have not replaced or newly installed complete sets of equipment with a high degree of automation on a large scale, they have also significantly improved product quality and production efficiency through equipment upgrades in key links. The advancement and thinking of intelligent manufacturing To a certain extent, the intelligentization of equipment solves the problem of insufficient labor and improves the competitiveness of China's textile industry. However, in the process of developing intelligence, there are indeed some problems, which are worthy of consideration and discussion by the industry. On the one hand, many entrepreneurs believe that the current simple machine substitution in the textile industry is not intelligent manufacturing. The real intelligent manufacturing is to replace human brain decision-making with accurate calculation and judgment of big data, and investment such as machine substitution is very important for textiles. Whether the business is worthwhile is debatable. A series of costs such as machine investment, maintenance, and upgrades are not low. Whether textile enterprises can absorb such expensive investment is also a problem that cannot be ignored. On the other hand, as a labor-intensive industry, on the one hand, intelligence can stimulate local investment and promote industrial upgrading, on the other hand, it means that a large number of workers may lose their jobs. How to resolve the contradiction between the two deserves further discussion. For intelligentization, the current guidance direction at the government level includes the following four points: establishing demonstration areas; improving intelligent manufacturing standards; promoting intelligent manufacturing supplier alliances; developing Internet +, big data and artificial intelligence. The intelligence of the textile industry has achieved some gratifying results. At the level of the Ministry of Industry and Information Technology, between 2015 and 2017, a total of 12 projects were included in the 'Intelligent Manufacturing Pilot Demonstration Project'; from 2016 to 2017, a total of 6 projects were included. Intelligent manufacturing comprehensive standardization project; 10 projects are included in the intelligent manufacturing new mode application project.

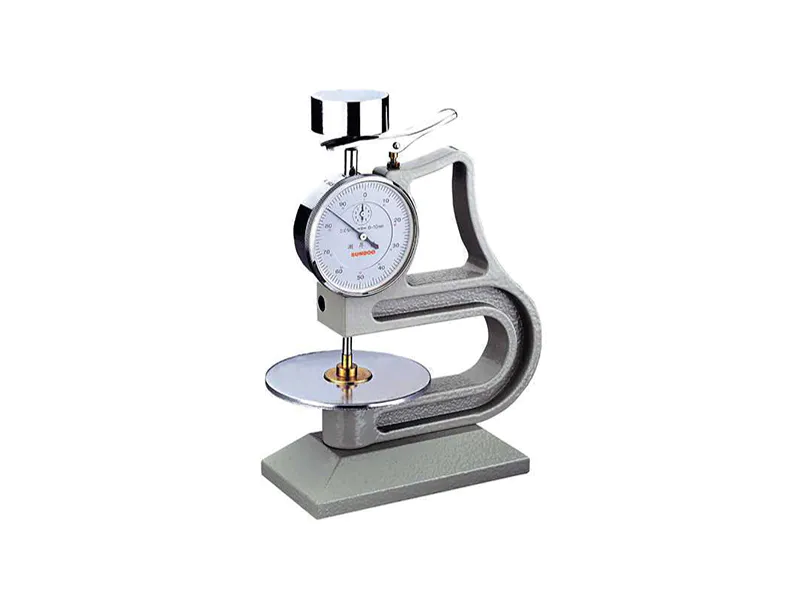

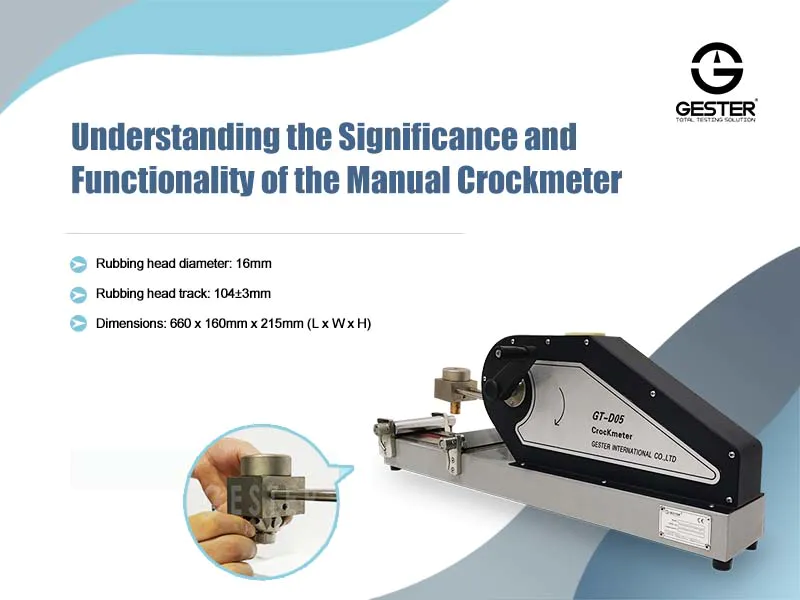

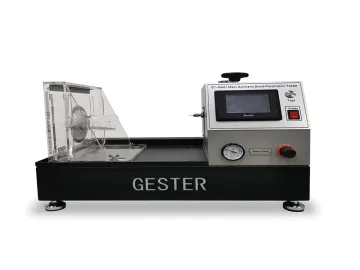

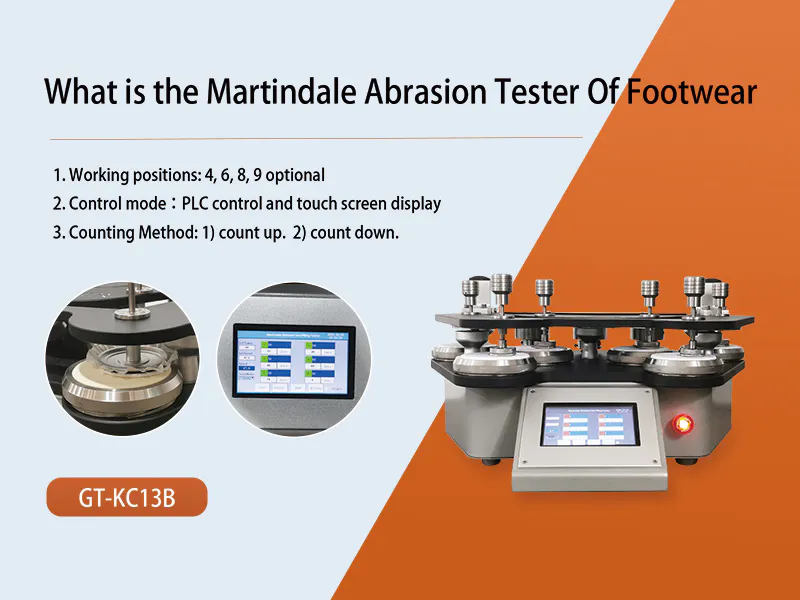

The textile testing equipment approach to tensile tester manufacturers is becoming increasingly popular; consequently, there is a surge in the demand for .

For details on textile testing equipment, see GESTER International Co.,Limited at GESTER Instruments.

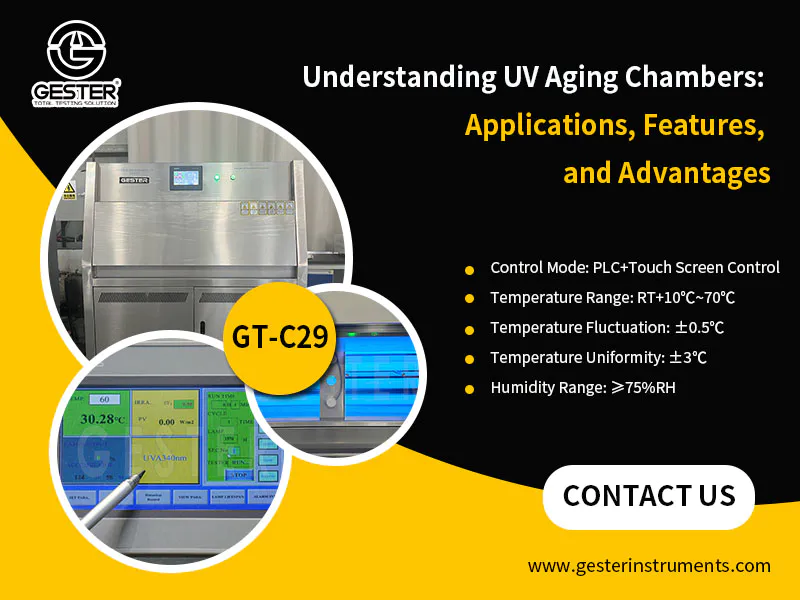

GESTER Instruments clearly and succinctly expresses what our company is all about. Strong brands cut through the noise to grab the audience and immediately shed light on the character of the product or service.

The textile testing equipment approach to tensile tester manufacturers is becoming increasingly popular; consequently, there is a surge in the demand for .

For details on textile testing equipment, see GESTER International Co.,Limited at GESTER Instruments.

GESTER Instruments clearly and succinctly expresses what our company is all about. Strong brands cut through the noise to grab the audience and immediately shed light on the character of the product or service.

Custom message