textile testing

How to use the hydrostatic pressure tester and matters needing attention

by:GESTER Instruments

2022-07-24

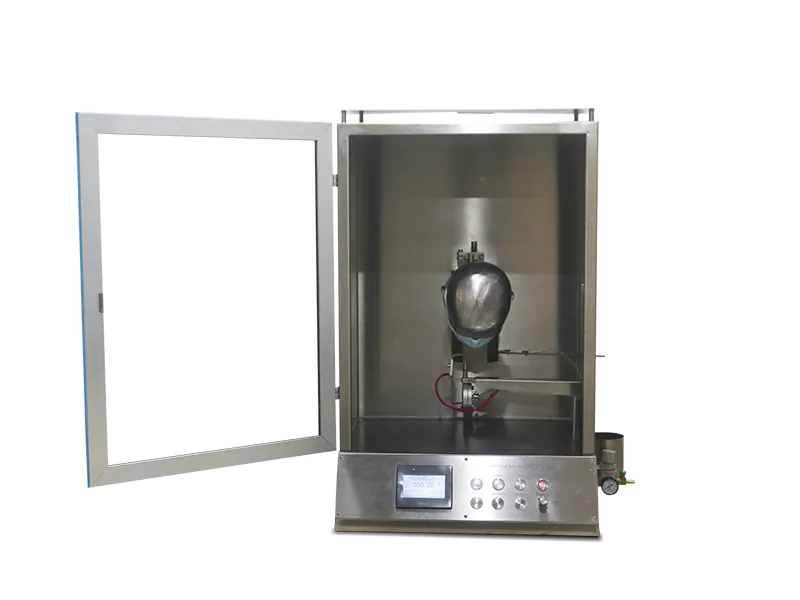

The hydrostatic pressure tester is suitable for measuring the water resistance of various fabrics and non-woven products that have undergone waterproof treatment, such as canvas, geotextile, tent cloth and other materials, also known as fabric hydrostatic pressure tester, fabric water permeability Measuring instrument, hydrostatic pressure tester, hydrostatic pressure testing machine, etc., the following is a brief introduction to the use of hydrostatic pressure resistance tester and precautions for the convenience of friends. 1. How to use the hydrostatic pressure tester: When using the hydrostatic pressure tester for testing, please operate in accordance with the instructions for use, and fully understand the test methods, standards and requirements in order to conduct the test correctly. 1. About 1200ml of distilled water is injected into the water tank of the test device. 2. Adjust the movable feet of the test device to keep the platform of the test device horizontal. 3. The pressure sensor of the test device, the water level control, and the plug of the electromagnetic pump are inserted into the socket behind the controller. 4. First, insert the three-core plug of the power cord into the power socket on the rear panel of the controller, and then connect the power plug to the 220V power supply. 5. Turn on the power switch, turn on the power,“Prepare”The indicator light is on, 6. Rate selection: You can choose the boost rate according to the standard, or customize the setting. 7. Rotate the handle of the left-handed test device to raise the triangular cover of the pressing cloth. After leveling the sample, turn the handle to the right to lower the triangular cover of the pressing cloth and clamp the cloth sample. 8. Close the drain valve on the test device. 9. Press the [Start] button,“Work”When the indicator light is on and the sample is sealed with the test hole, the test hole gradually builds up water pressure, and the hydrostatic pressure on the sample is displayed by the digital tube. 10. The ISO 811 evaluation method stipulates that when the third water droplet just appears on the sample, press the [Stop] button, and the instrument returns to the“Prepare”state, the display value of the digital tube is latched, and the latched display value is the test result. 11. Record the test results and open the water valve. Put the distilled water in the test hole back into the tank. 12. Press the [Reset] button to release the latched display value and reset the instrument program. 13. Remove the sample for the next test. 2. Precautions for using the hydrostatic pressure tester: 1. When the test is carried out under general atmospheric conditions, the temperature and humidity of the test site should be prevented from changing too much. 2. The test water must be distilled water and be changed frequently. 3. When the instrument is working by pressing the [Start] button, in addition to stopping the test, the [Stop] button cannot be pressed in the middle of the test, otherwise the test must be restarted. 4. During the test, in order to remove the air in the test hole, the water and the cloth are in direct contact. Before the test, fill the test hole with water (close the drain valve and press the [Start] button. When the test hole is filled with water, press [Stop] button, press [Reset] button) and then put the cloth sample for testing. 5. The standard points out that the results obtained at different rates may be different, so which rate should be selected should be indicated on the test report. It is recommended to use the 10 cmH2O rate file when the water pressure resistance of the fabric sample is low, and select the 60 cmH2O rate file when the water pressure resistance is high. Test with standard rate. 6. If the instrument is not used for a long time, the water in the water storage tank must be drained, and the water level electrode and the water tank shell should be short-circuited with a metal object (such as a screwdriver), and the instrument should be turned on to let the pressure run for 10 seconds to remove the stored water. 7. When the pressed operation key is valid, you will hear a beep“beep”the answer sound. Otherwise, the keys are invalid (when operating out of sequence of operations). 8. When the water level is lower than the electrode level: the buzzer will sound“beep”A long beep until the water is filled to a sufficient level. At this time, all keys are invalid. (protect the electromagnetic pump) 9. When the water pressure reaches the maximum value: the buzzer will sound“beep..beep..”A sound prompt will be heard, and the prompt will end after a few seconds. At this point, the instrument is already in the [Stop] state. 10. During the test, if you hear the buzzer beeping rapidly“beep..beep..”A sound prompt is displayed, and the test process is automatically terminated. Indicates that there is not enough water, and too much automatic peeling causes the sensor to exceed the range (protect the sensor)

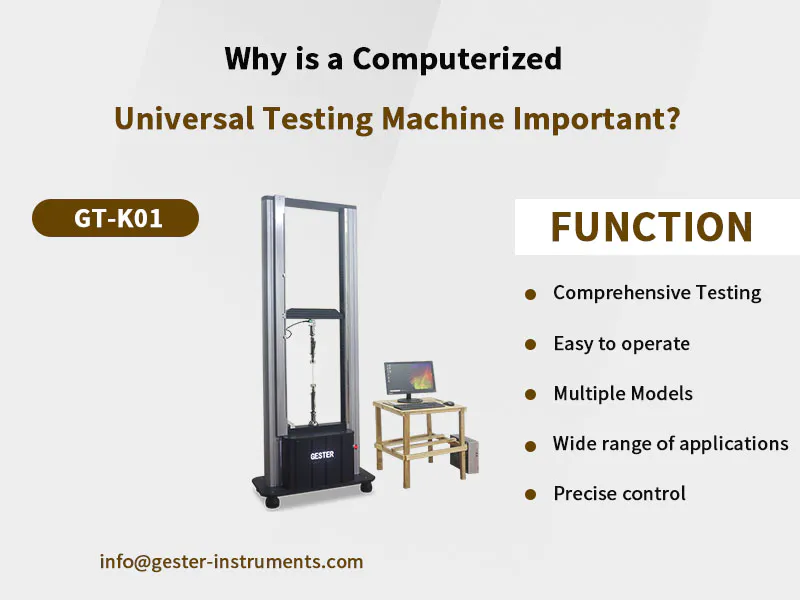

Technology is a foundational component of today's fast-paced business environment. GESTER International Co.,Limited who are digital natives are especially equipped to harness technology's power to establish, promote and grow our businesses.

have become more diverse in appearance and function thanks to the advanced technology. Choose a that you can trust to deliver an excellent user experience reliable performance at GESTER Instruments.

Lucky to know that you are not alone in the face of tensile tester manufacturers issue. Let GESTER International Co.,Limited be your selected textile testing equipment expert in providing first class to help you out.

Technology is a foundational component of today's fast-paced business environment. GESTER International Co.,Limited who are digital natives are especially equipped to harness technology's power to establish, promote and grow our businesses.

have become more diverse in appearance and function thanks to the advanced technology. Choose a that you can trust to deliver an excellent user experience reliable performance at GESTER Instruments.

Lucky to know that you are not alone in the face of tensile tester manufacturers issue. Let GESTER International Co.,Limited be your selected textile testing equipment expert in providing first class to help you out.

Custom message