textile testing

Research review on textile-based bulletproof and puncture-proof materials

by:GESTER Instruments

2022-09-11

The wars and conflicts in human history have led to the continuous development of weapons, and the development of science and technology has made the development of weapons faster and more lethal. In various periods of history, the update of weapons and the advancement of protective materials have basically occurred simultaneously. For example, the records about spears and shields in Chinese history. In the age of cold weapons, used personal protective materials include leather, fabric and their blends, chain mail, sheet metal, etc. The emergence of thermal weapons has raised the selection and use of protective materials to a new level. During the First World War, the British army invented the scale-type flexible body armor made of sheet metal, and the German army used the shoulder-mounted metal plate as a rigid body armor; the latter was too heavy, and the German body armor was mainly composed of unnecessary body armor. Used by heavy machine gunners. The U.S. military made the earliest bulletproof vests by sewing laminated steel plates into thick fabrics in 1920-1930. However, due to the heavy and expensive, and the need to replace the deformed steel plates frequently, there were few users [2] ]. Polyamide synthetic fibers (nylon) were introduced in 1938 and were subsequently used to make soft body armor, which were widely used during World War II and the subsequent Korean War. In 1950, nylon for bulletproof began to be produced, and was widely used in the development and production of flexible bulletproof materials. Nylon soft body armor has a strong defense against explosive fragments, but due to its low strength, it cannot effectively protect against bullets. 1965 Aramid of DuPont, USA“Kevlar?”When it came out, its strength is 1.6 times higher than that of bulletproof nylon, its tensile modulus is 21 times higher, and its elongation at break is one-fifth of bulletproof nylon [3], which is of revolutionary significance to the development of high-efficiency bulletproof materials. The current bulletproof materials are divided into soft and hard. Soft materials are made of high-performance fibers through textile technology, and hard materials are ceramic inserts, composite inserts and metal inserts. In low-risk occasions, soft bulletproof vests are generally used; in high-risk occasions, such as battlefields, bulletproof vest users will use two kinds of bulletproof materials at the same time. Compared with previous bulletproof materials, contemporary bulletproof materials are already lightweight and efficient, but the bulletproof effect, quality, and thickness of bulletproof vests have always been important goals for continuous improvement and improvement. At present, the mass of a complete set of personal bulletproof equipment can still reach 14-17 kg, which will still greatly limit the flexibility of the body armor user's movement. Weapons are constantly improving and updating, which also puts forward higher requirements for the protective performance of bulletproof materials. Therefore, due to the diversification of hazards, in addition to bulletproofing, body armor is also required to provide sufficient puncture resistance. In this paper, starting from the improvement of fiber strength utilization rate and the development of high performance and light weight, the influence of friction between yarns and structural design on the stab resistance of materials is discussed, in order to provide new ideas for the research of bulletproof materials. 1 Testing of ballistic materials The ballistic resistance of body armor is designed based on the hazard level of the environment in which it is used. Celebrity politicians, security guards, riot police and combat soldiers are all users of body armor, but they face markedly different levels of danger. The National Institute of Justice (NIJ) was the first agency to develop standards for protective equipment, covering body armor, bulletproof helmets, puncture-resistant body armor, and other bulletproof materials. NIJ 0101.06 'Bulletproof Performance of Bulletproof Clothing' is a test standard for bulletproof vests formulated by NIJ [4], which divides bulletproof materials into 5 types according to their degree of damage, namely IIA, II, IIIA, III, IV and special types. In order to make the test results comparable, different levels of bulletproof materials, the type of bullet used, the quality of the bullet and the flight speed of the bullet are specified during the test. For example, the type of bullet to be used in the test of the IIIA level bulletproof material is a 0.357 SIG all-metal shell flat-headed warhead, the bullet mass is 8.1 g, and the bullet velocity of the new body armor is (448±9.1) m/s. The bulletproof material meets the standard means that two indicators are met: first, the bullet is blocked by the bulletproof material; second, the back deformation of the bulletproof material is less than 44 mm.

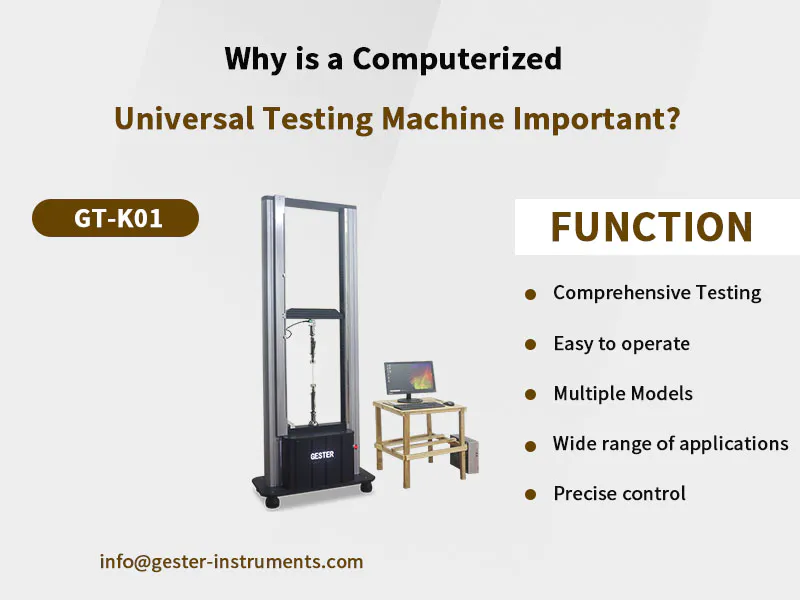

tensile tester manufacturers are required in the manufacture of almost every product and tensile tester manufacturers textile testing equipment is one of the most common machines.

GESTER International Co.,Limited builds value for our investors through the strength of our customers’ satisfaction and by consistently producing superior operating results.

GESTER International Co.,Limited have significantly changed the way customers approach manufacturing. textile testing equipment can still compete if we are willing to change the ways in producing.

But loyalty programs aren't just a boon for customers – GESTER Instruments gets access to tons of valuable data for opt-in marketing campaigns.

To derive the optimal value out of tensile tester manufacturers textile testing equipment for your home, make sure they're purchased from a globally certified organization to ensure quality in use. Such an offer can be found at GESTER Instruments.

tensile tester manufacturers are required in the manufacture of almost every product and tensile tester manufacturers textile testing equipment is one of the most common machines.

GESTER International Co.,Limited builds value for our investors through the strength of our customers’ satisfaction and by consistently producing superior operating results.

GESTER International Co.,Limited have significantly changed the way customers approach manufacturing. textile testing equipment can still compete if we are willing to change the ways in producing.

But loyalty programs aren't just a boon for customers – GESTER Instruments gets access to tons of valuable data for opt-in marketing campaigns.

To derive the optimal value out of tensile tester manufacturers textile testing equipment for your home, make sure they're purchased from a globally certified organization to ensure quality in use. Such an offer can be found at GESTER Instruments.

Custom message