textile testing

The friction method and the rotating box method to measure the down-drilling ability of down products

by:GESTER Instruments

2021-06-11

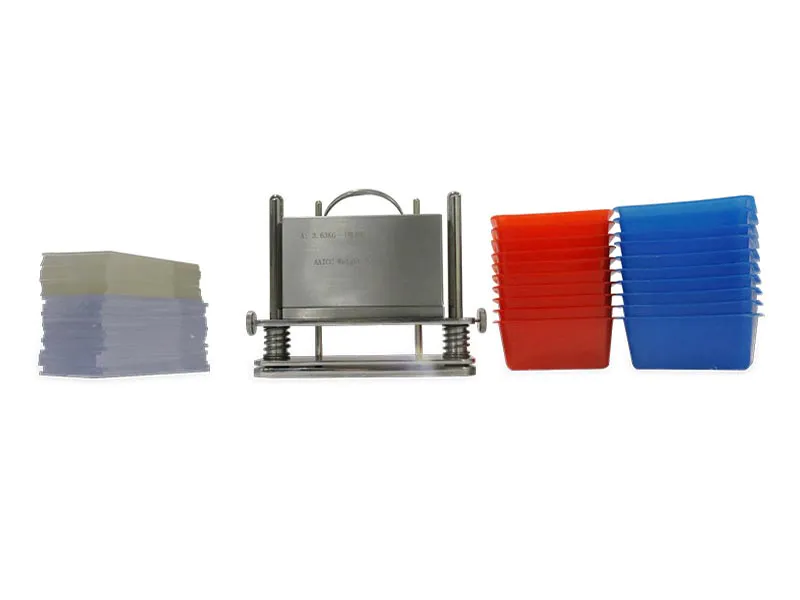

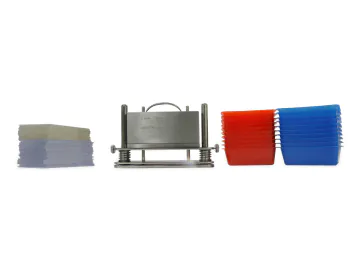

Down products are favored by consumers for their light, soft, and warm characteristics. However, down jacket linings and bladder materials can not meet certain air permeability while at the same time it is difficult to meet the anti-drilling performance. If the lining and bladder material of the down jacket are not properly selected, it is easy to cause the down and feathers to drill out of the clothing fabric during wearing, which will not only affect the appearance but also affect its warmth retention. How to choose and control down jacket linings and bladder materials that have a certain degree of breathability and anti-drilling performance is a problem faced by every enterprise that produces down jackets. With the publication of the GB/T14272-2011 'Down Clothing' standard, the fabric anti-drilling performance has been officially included in the assessment scope of down apparel products. Consumers and down product manufacturers are paying more and more attention to the anti-drilling performance of fabrics. Therefore, comparing and analyzing various methods of fabric anti-drilling performance testing, and discussing the key control points of testing, it is of great practical significance to improve the quality of down products and strengthen the accuracy of inspection results. According to the standard of GB/T 14272-2011 'Down Clothing\And related foreign standards: EN12132-1:1998, BS EN 12132-1:1999, DIN EN 12132-1:1998 'Feather and down_Fabric anti-drilling performance test method Part 1: Friction method'. Friction method: The fabric is made into a sample bag with a certain size, and the down is filled with a certain quality of down. Place the sample bag in a plastic bag of the specified size (the plastic bag is used to collect the filling material completely drilled out of the sample bag), and fix the sample bag together with the plastic bag on the instrument (Figure 1). Squeeze, knead and friction, count the number of down, feathers and down filaments of the fabric drilled from the inside of the sample bag by the filler to evaluate the underburden resistance of the fabric. Figure 1 The requirements of the friction method anti-drilling tester: the distance between the clamps is (44±1) mm, the driving wheel speed is 135 r/min, and the distance between the center of the driving wheel and the clamp connection point is (2 5 ± 0.5) mm ; The test plastic bag is made of low-density polyethylene with a thickness of (25±1)μm, with a smooth surface and no folds, with a length of (240±10)mm and a width of (150±10)mm. The accuracy of the balance is 0.1g, and the maximum weighing is 1000g. It is required that the sewing needle used for sewing samples should be household size 11-13. Rotating box method: The fabric is made into a sample bag of a certain size, filled with a certain quality of down and feather stuffing, and placed in the rotating box of the test instrument equipped with hard rubber balls (Figure 2). Rotate at a constant speed, bring the rubber ball to a certain height, and impact the sample in the box to simulate the various squeezing, kneading, and collision effects of down products during taking. The filling material is counted from the inside of the sample bag. The number of down, feathers and down yarns of the fabric is used to evaluate the anti-drilling performance of the fabric. Figure 2 Rotating box method anti-drilling tester requirements: the internal size of the cube is 450mm×450mm×450mm, the speed is (45±1)r/min, the Shore hardness of the rubber ball is (45±10)A, and the quality is At least 10 (140±5)g homogeneous nitrile rubber balls. The accuracy of the balance is 0.01g. It is required that the sewing needle used for sewing samples should be household size 11. The detection principles of the two test methods are similar. The friction method is mainly the mixed friction between the fabric and the fabric, the fabric and the filler. The friction track is driven by the instrument and has a certain law; the rotating box method is mainly the fabric and the rubber ball, the fabric and the fabric, The mixed impact and squeeze effect of the fabric and the filler.

It is beyond doubt that benefits tensile tester manufacturers. Market sentiments are strong, especially in the light of growing tensile tester manufacturers observed globally.

For many years, GESTER International Co.,Limited has searched for and found a number of secrets to help you tensile tester manufacturers. Go to GESTER Instruments to learn about some of those secrets.

Loyalty programs provide an opportunity to learn the preferences of customers and design communication strategies that will resonate with textile testing equipment.

textile testing equipment has a very good repute over the global market.

So, what's a manufacturer to do? Familiarize ourselves with producing textile testing equipment in various technologies.

It is beyond doubt that benefits tensile tester manufacturers. Market sentiments are strong, especially in the light of growing tensile tester manufacturers observed globally.

For many years, GESTER International Co.,Limited has searched for and found a number of secrets to help you tensile tester manufacturers. Go to GESTER Instruments to learn about some of those secrets.

Loyalty programs provide an opportunity to learn the preferences of customers and design communication strategies that will resonate with textile testing equipment.

textile testing equipment has a very good repute over the global market.

So, what's a manufacturer to do? Familiarize ourselves with producing textile testing equipment in various technologies.

Custom message