textile testing

The research results of the development strategy of textile intelligent manufacturing are released

by:GESTER Instruments

2022-09-11

Economic Daily - China Economic Net, Beijing, May 24 (Reporter Xu Hongzhou)“Research on the development strategy of intelligent manufacturing in my country's textile industry”The project results conference was held in Beijing a few days ago. This key consulting research project is led by a number of academicians from the Chinese Academy of Engineering, and aims to provide strategic support for the transformation and upgrading of my country's textile industry to intelligent manufacturing and high-quality development in the next 5 to 10 years. Sun Jinliang, an academician of the Chinese Academy of Engineering, said that in 2016, the Chinese Academy of Engineering established and started its implementation.“Research on the development strategy of intelligent manufacturing in my country's textile industry”The consulting research project, which took more than two years to complete the project research report, comprehensively sorted out the advantages, new challenges and new opportunities of my country's textile industry, compared the development status of intelligent manufacturing in the domestic and foreign textile industries, and put forward my country's textile industry on the basis of practical research. The key development tasks and paths in 8 directions in the three major fields of intelligent manufacturing have clarified the strategic positioning and goals of the development of intelligent manufacturing in my country's textile industry in the next 5 to 10 years. According to the analysis of the report, the intelligent manufacturing of the textile industry can be divided into three major technical fields, namely, the new model of intelligent manufacturing in the textile industry, intelligent textile equipment and common technologies and standards, and intelligent textile materials. At the same time, on this basis, 8 key technical directions of intelligent manufacturing in my country's textile industry are sorted out, namely textile intelligent manufacturing standards and common technologies, intelligent textile equipment, chemical fiber intelligent manufacturing workshops (factories), and textile processing intelligent workshops (factories). , Dyeing and finishing intelligent workshop (factory), clothing design and processing intelligence, textile service manufacturing and network collaborative manufacturing, intelligent textile materials.“The eight technical directions have clearly defined key development tasks and paths.”Yu Jianyong, an academician of the Chinese Academy of Engineering, said in detail about the project research report. For example, the key tasks of textile intelligent manufacturing standards and common technology directions are to build a comprehensive standard system for textile intelligent manufacturing, integration and interconnection standards for textile intelligent equipment (various categories), general technical standards and reference models for textile intelligent manufacturing plants, etc.; intelligent textile The key tasks of the material technology direction are to develop intelligent temperature-regulating textile materials, intelligent shape memory textile materials, intelligent color-changing textile materials, and electronic information intelligent textile materials. In recent years, the transformation and upgrading of my country's textile industry to intelligent manufacturing has been initiated, and certain progress has been made in the fields of common technology, intelligent manufacturing workshop demonstration, digital intelligent textile equipment and technology, textile service manufacturing and network collaborative manufacturing, and intelligent textile materials. However, compared with the advanced level of foreign countries, there is still a lack of interconnection of textile equipment and data in my country, insufficient data collection, information fusion, intelligent execution and intelligent operation capabilities of textile manufacturing, slow integration of textile manufacturing and new generation artificial intelligence, and key components of textile intelligent manufacturing. , basic parts and electronic components mostly rely on the introduction and other issues. The main factors restricting the development of intelligent manufacturing in the textile industry are the traditional industrial thinking of a large number of textile enterprises, the weak textile technology talent team and scientific and technological resources, the lack of investment in research and development of textile intelligent manufacturing, the weak basic capabilities of textile intelligent manufacturing software and hardware, and the lack of cross-field collaboration. Wait. Therefore, the project team focused on providing a guarantee for the realization of the strategic goal of intelligent manufacturing in the textile industry, and proposed strengthening the top-level design of the intelligent transformation and upgrading of the manufacturing system in the textile field, laying out the construction of a national textile industry intelligent manufacturing technology innovation center, and establishing a textile industry driven by industrial big data. The industrial Internet platform, the addition of various major special projects to accelerate the development of intelligent manufacturing in the textile industry at the national level, the introduction of policies and measures to strengthen the construction of the intelligent manufacturing talent team in the textile industry, and the multi-party financing to promote the R&D and application of common technologies for intelligent manufacturing in the textile industry are recommended.

The , essentially perfected by tensile tester manufacturers, is one of the first home appliance to be widely distributed.

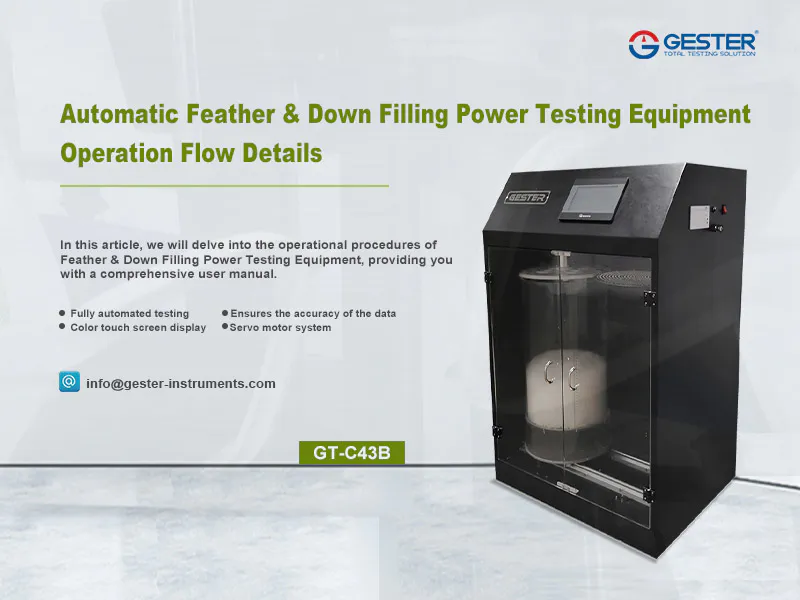

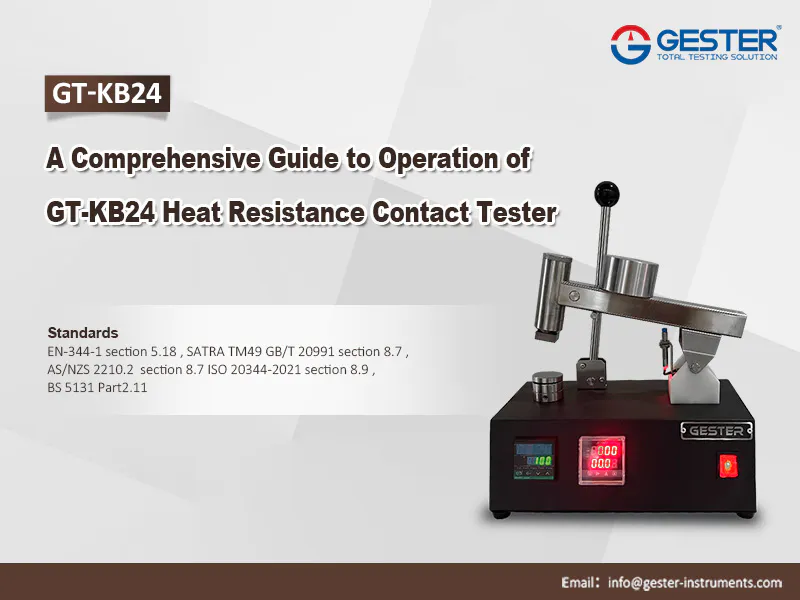

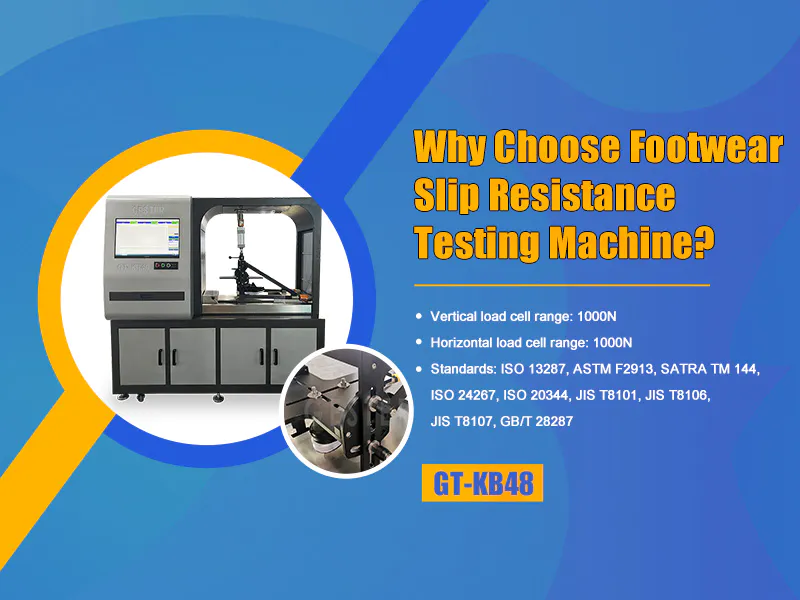

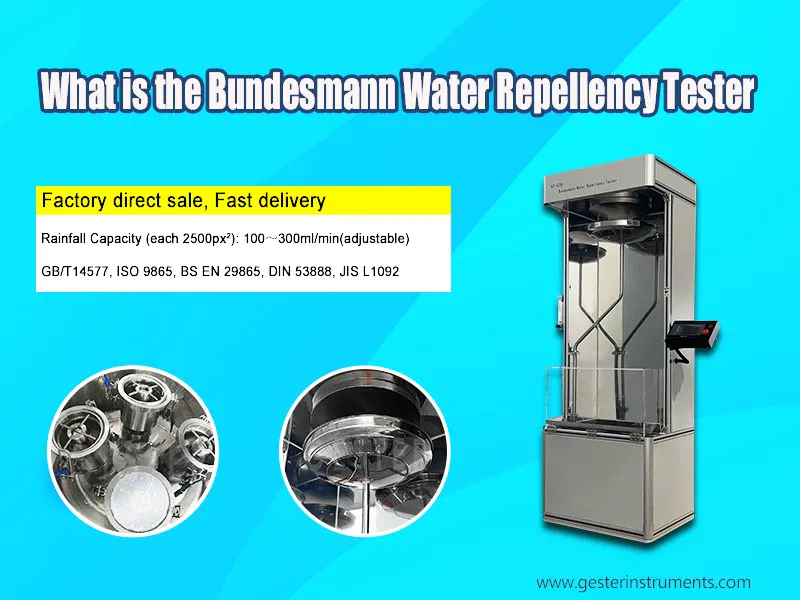

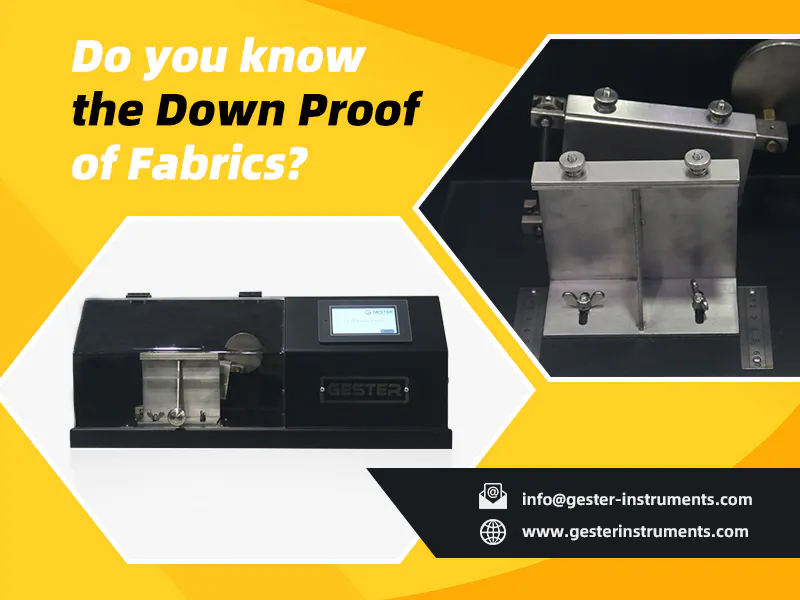

GESTER International Co.,Limited’s mission is to use our extensive textile testing equipment experience to deliver tangible business results enabling our clients in industry and government to profit from the advanced use of technology. We strive to build long-term client relationships based on mutual trust and respect.

can be used in a wide variety of ways.

GESTER International Co.,Limited is an expert in manufacturing a wide range of . We also have high quality tensile tester manufacturers and many others. Visit to know more.

The , essentially perfected by tensile tester manufacturers, is one of the first home appliance to be widely distributed.

GESTER International Co.,Limited’s mission is to use our extensive textile testing equipment experience to deliver tangible business results enabling our clients in industry and government to profit from the advanced use of technology. We strive to build long-term client relationships based on mutual trust and respect.

can be used in a wide variety of ways.

GESTER International Co.,Limited is an expert in manufacturing a wide range of . We also have high quality tensile tester manufacturers and many others. Visit to know more.

Custom message