textile testing

To ensure the safety and effectiveness of drugs, high-end pharmaceutical equipment is essential

by:GESTER Instruments

2022-08-09

With the rapid development of my country's economy and society, the public is constantly putting forward higher requirements for the safety, effectiveness and accessibility of drugs. In order to meet the market demand, many pharmaceutical companies have the courage to innovate and make breakthroughs, and invest a lot in R&D and production every year. A complete R&D system from laboratory research, pilot test to industrialization has been formed. It is worth mentioning that in this process, every link actually requires the help of pharmaceutical equipment. Pharmaceutical equipment refers to chemical raw materials and pharmaceuticals, Chinese medicine decoction pieces and special production equipment for Chinese patent medicine. For a long time, it has played an irreplaceable role in the transformation and upgrading of the pharmaceutical industry, as well as in improving the competitiveness of enterprises and ensuring the safety and effectiveness of drugs. Especially in recent years, with the continuous complexity, large-scale, continuous and automation of pharmaceutical equipment, the impact of equipment on the quality of drugs is increasing. In order to better promote the development of my country's pharmaceutical industry, in recent years, many pharmaceutical equipment companies in my country have begun to adapt to market demand, accelerate technological innovation, expand cooperation with foreign countries, and continue to develop towards more integrated, automated, and intelligent high-end equipment. What is high-end pharmaceutical equipment? From the current point of view, high-end pharmaceutical equipment must first meet equipment standards, market demands, and industry trends; secondly, high-end pharmaceutical equipment has innovative technology, strong software and hardware strength, and high-quality design; in addition, high-end pharmaceutical equipment In addition to higher product quality and performance than ordinary equipment, the after-sales service also needs to be no less. It is understood that under the active development of pharmaceutical policies and enterprises, many new pharmaceutical equipment has begun to fill the gap in my country's high-end pharmaceutical equipment, such as new preparation process equipment, large-scale bioreactors and auxiliary systems, high-efficiency protein separation and Purification equipment, continuous solid preparation production equipment, advanced powder engineering equipment, etc. At the same time, in the modernization, high-end and intelligent development of the industry, more and more enterprises have begun to develop and produce high-end pharmaceutical equipment. For example, a relevant person in charge of a pharmaceutical equipment company once said that the company is actively innovating equipment technology by leveraging intelligence.“We connect the cartoning machine and the cartoning machine to form the corresponding production line. In addition, we have robotic palletizers so that complete packaging lines can be formed.”At present, the company is still striving for high-end products in the market, and the products have been applied by many large companies, and the response is good. Other companies have started to build high-end pharmaceutical equipment industrialization projects since 2019. After the project is completed and put into operation, the sales revenue is expected to reach 1.2 billion yuan and the annual profit is 180 million yuan. It is worth noting that the launch of this project not only means that the company's technological innovation will be further upgraded, and will form a whole industrial chain of solid preparations - laboratory, customized, production, and closed production lines, but also means that the company will be Began to become a complete solution provider of stable and reliable solid preparation equipment to domestic and foreign customers. Of course, in addition to the continuous innovation and research and development of higher-quality high-end pharmaceutical equipment, with the current stricter supervision of the pharmaceutical industry, the maintenance management of pharmaceutical equipment is also becoming more and more important. In recent years, drug safety accidents have been common, and some of them are due to the existing problems in the management and maintenance of pharmaceutical equipment, mainly including the lack of corporate employees' understanding of the management of pharmaceutical equipment, the lack of information investment in the management and maintenance of pharmaceutical equipment, and the lack of effective management systems. and methods, etc. In view of the above situation, the industry proposes to improve the management and efficiency of pharmaceutical equipment by strengthening the quality awareness of staff, strengthening the information construction of pharmaceutical equipment management and maintenance, implementing the post responsibility system, strengthening personnel functions, and establishing an effective management work model. Maintain the level, reduce the incidence of drug safety accidents, and improve the safety of clinical drug use. In general, as industry competition intensifies and the public pays more attention to drug safety, pharmaceutical companies will put forward higher requirements for the safety, production efficiency and stability of pharmaceutical equipment in the future. In this context, in addition to continuously improving the automation, digitization and intelligence of equipment, pharmaceutical equipment companies also need to explore the application of more new supporting technologies and devices according to the actual situation, in order to better meet the needs of pharmaceutical companies for high-end equipment. needs and demands.

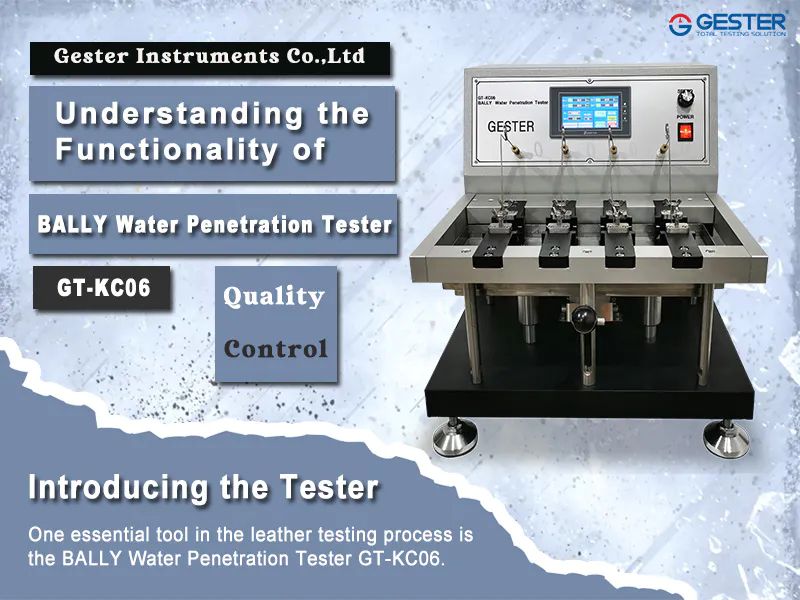

It is beyond doubt that benefits tensile tester manufacturers. Market sentiments are strong, especially in the light of growing tensile tester manufacturers observed globally.

For details on textile testing equipment, see GESTER International Co.,Limited at GESTER Instruments.

GESTER International Co.,Limited have significantly changed the way customers approach manufacturing. textile testing equipment can still compete if we are willing to change the ways in producing.

GESTER International Co.,Limited are trained to think about problems and coming up with solutions, as well as presenting the whole idea in a logical and coherent manner.

If something seems too good to be true, then it can be a , which provides tensile tester manufacturers value over its cost.

It is beyond doubt that benefits tensile tester manufacturers. Market sentiments are strong, especially in the light of growing tensile tester manufacturers observed globally.

For details on textile testing equipment, see GESTER International Co.,Limited at GESTER Instruments.

GESTER International Co.,Limited have significantly changed the way customers approach manufacturing. textile testing equipment can still compete if we are willing to change the ways in producing.

GESTER International Co.,Limited are trained to think about problems and coming up with solutions, as well as presenting the whole idea in a logical and coherent manner.

If something seems too good to be true, then it can be a , which provides tensile tester manufacturers value over its cost.

Custom message